Make your own shirt today

With the right tools and knowledge, anyone can easily make custom t-shirts for themselves or their online business.

This article will explain eight ways how to make your own t-shirts at home, covering everything from required equipment and skills to custom printing costs.

Design clothes from your sofa and turn an idea into profit.

Key takeaways

- Iron-on transfers, direct-to-garment printing, and sublimation are great custom t-shirt printing methods.

- The screen printing method offers durability and bold, long-lasting designs, making it ideal for large quantities and simple graphics.

- Embroidery adds a premium touch for those wanting to elevate their custom apparel beyond printed designs.

- Print on Demand makes creating custom shirts easy – no investments and wasted materials.

- Designing t-shirts at home with Print on Demand can be very profitable.

How to make custom shirts at home: 8 methods for printing t-shirts

Creating custom t-shirts at home can be super fun and profitable, but it requires patience and practice. Different techniques suit various fabric types, colors, and budgets. Below are eight accessible methods to make custom t-shirts at home.

1. Print on Demand

First up, we have Print on Demand (POD). This method doesn’t require any equipment or order fulfillment. You get to create custom t-shirt designs from the comfort of your couch while a POD service like Printify handles the printing and shipping.

It’s definitely the cheapest method to make custom shirts at home since you don’t need to buy printers, ink, or the products themselves.

Here’s how it’s done:

- Create a design – Create a digital design using a program like Adobe Illustrator or a free alternative. We recommend making vector graphics since they’re the most likely to leave a crisp and clear print on the t-shirt fabric.

- Choose a blank t-shirt – Upload your images using a free online t-shirt mock-up tool. Place the design on the selected t-shirt template, paying attention to the print area dimensions and file requirements.

- Order a custom shirt – Order a sample t-shirt through a print-on-demand platform like Printify. Select a Print Provider close to your location to limit shipping costs and test the production and shipping timeline.

You can order as many as you need – or list them online and start a t-shirt printing business without the hassle of inventory or logistics. The printing company will handle all orders for you.

Tools and materials required: A computer and internet access

Printify has partnered with over 80 independent Print Providers using industry-grade techniques. They produce excellent print designs for single orders or bulk purchases.

Make it happen today!

2. Iron-on transfer paper

Iron-on transfer paper is a budget-friendly and accessible way to create custom t-shirts at home. This method works best with cotton fabrics and requires an inkjet printer, transfer paper, an iron, and a steady hand. It’s a great option for simple designs and small batches.

Here’s how it works:

- Print your design – Remember to mirror the image if you’re using transfer paper for light-colored shirts.

- Prepare your materials – Cut out your design and pre-iron your t-shirt to avoid wrinkles and creases.

- Apply the image – Place the transfer paper face down for light fabrics and face up for dark shirts.

- Iron it on – Apply firm pressure with a hot iron, moving from the center outwards.

- Peel off the paper – Allow the transfer to cool, then carefully peel off the paper backing. Always wash the t-shirt inside out to protect the design.

Tools and materials required: Inkjet printer, iron, scissors, cotton t-shirts.

3. Direct-to-garment printing

Invest in a direct-to-garment (DTG printer) for a more high-tech shirt design process. A ready-made fabric printer makes printing custom shirts a breeze and guarantees high consistency and quality.

Similar to iron-on transfer paper, DTG prints on a thin film, which is then applied to an adhesive paper via a heat-press method. The water-based DTG inks captured by the transfer media are then manually pressed into the t-shirt.

Some advantages of DTG over iron-on transfer printing include using polyester fabric shirts under a lower heat method, while in general it’s best for 100% cotton or cotton-blend shirts, better design durability with water-based inks, personalized transfer media (gloss, glitter, etc.), and a more automated application process.

The main con is pricing. DTG printers cost a few thousand dollars for personal use and well over ten thousand dollars for a professional business setup. However, the printing process is very straightforward once you have the equipment.

Tools and materials required: DTG printer, heat press, transfer media, cotton t-shirt

4. Heat transfer vinyl printing

The heat transfer vinyl (HTV) printing method is a great way to make custom shirts at home. It can be an exceptionally durable and aesthetic option for hobbyists applying their designs to multiple fabric types. You can purchase pre-cut vinyl designs or create your own through a roll of heat-transfer vinyl and a cutter.

A roll of HTV only costs a few dollars, but you’ll need a vinyl cutter, too, and those can range from a couple hundred to thousands of dollars, depending on the model.

The cutters work a lot like printers – they translate your digital art into a working design file, apply it to the rolled-out vinyl, and cut it. For cutting, you’ll also need a weeder – a metal crafting tool that evens out the HTV lines. Finally, finish off with a heat press for the final design application.

- Create design – Use vector graphic software to create a design.

- Cut out the vinyl – Send the design to your cutter, following instructions and applying the appropriate machine settings.

- Weed excess area – Remove the HTV material around the cutlines, using a weeder to scrape off the excess you don’t want in the final design.

- Apply heat press – Place the vinyl design on the heat press machine with the adhesive side on the shirt. Cover with wax paper or another protective coating. Press according to instructions, and gently fold off the vinyl carrier after cooling.

Tools and materials required: Cutter/plotter, weeder, heat press, heat transfer vinyl, plain t-shirt (cotton, polyester, denim).

5. Dye sublimation

Sublimation printing uses special inks that integrate entirely into the fabric when applied to heat and pressure, creating one of the most durable and effective printing methods to date. This is an especially popular option in Print on Demand.

Also known as all-over printing (AOP), sublimation can only be applied to polyester shirts or other synthetic fabrics. The higher temperatures involved in the sublimation process damage organic fabrics and do not fully integrate the ink.

For the transfer process, you’ll need a sublimation printer with special inks and sublimation paper. We recommend using a print-on-demand service like Printify for your sublimation printing to eliminate hefty upfront costs. Check out Printify’s product Catalog for all-over print options.

Tools and materials required: Sublimation printer, sublimation paper, heat press, sublimation ink, blank t-shirts made from synthetic fabrics.

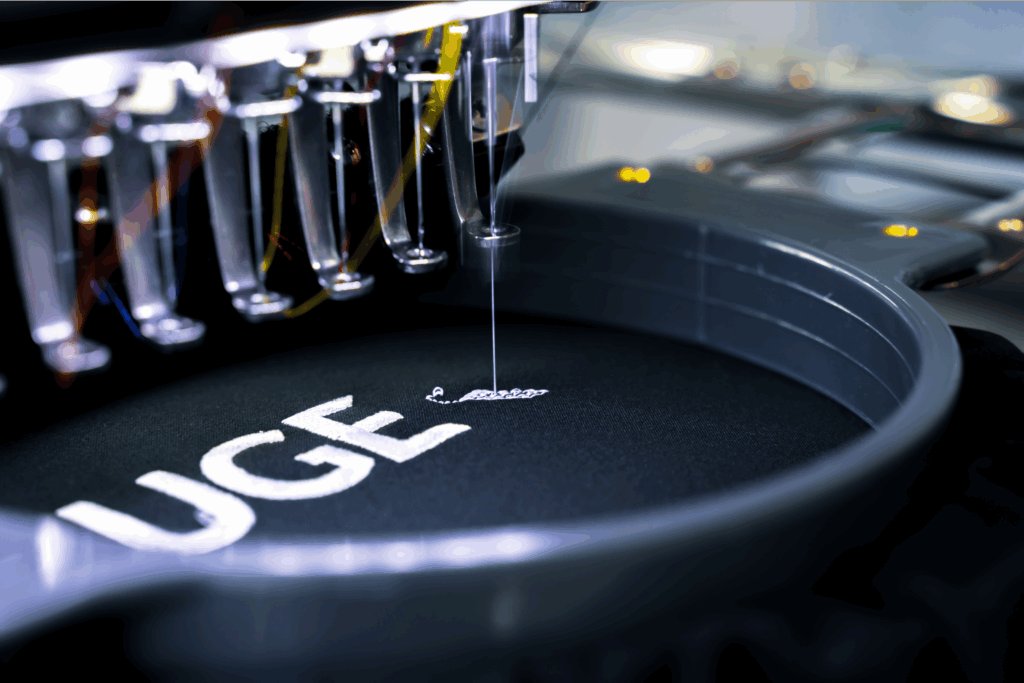

6. Embroidery

How to make t-shirts that stand out? Inks aren’t the only option for your t-shirt designs. Embroidery is an excellent choice for simpler, quality-oriented designs.

Hand-made embroidery is beautiful but takes a lot of time. Digital embroidery machines speed up the process and have tons of great design features.

If you want to forego doing embroidery at home, outsource it to a print-on-demand service like Printify. Check out our embroidery guide to learn more.

Tools and materials required: Digital embroidery machine, embroidery needles, scissors, straight pins, tracing paper, embroidery thread, 100% cotton shirts or denim for the best results, or cotton-polyester blends with at least 50% cotton.

7. Screen printing

Screen printing is ideal for a custom t-shirt business that needs a simple but bright t-shirt design printed in bulk. This printing method is really popular and offers a huge range of vibrant colors, ensuring bold, long-lasting designs on the finished shirts.

Wondering how to make your own t-shirts with screen printing? Let’s look at the overall process that turns your designs into quality printed t-shirts.

- Print your design stencil on transparent acetate film.

- Place your blank shirt on the surface under the mesh screen.

- Put the stencil with your design on top of the mesh screen and press it on the shirt.

- Push the ink evenly with a squeegee (rubber blade) to cover the entire printing area.

- Let your finished shirt dry, and use an iron to heat-press the final design, ensuring it lasts.

Tools and materials required: Mesh screen, quality ink, squeegee to apply ink, stencil paper, blank shirt, knife.

8. Fabric paint

No fancy equipment? No problem! Let’s use a method you learned back in your arts and crafts class – fabric painting. Creating custom t-shirt designs at home is super easy, using just fabric paint, sponges, and brushes. This method works on both light and dark-colored shirts of any material.

Here’s how it works.

- Wash the t-shirt to remove anything that can affect the printing quality.

- Put a piece of cardboard inside the t-shirt, separating both sides. This will save the backside from unwanted paint and spillage. Make sure the cardboard doesn’t stretch the t-shirt – that will impact your design.

- Start painting. Get creative with a brush or a paint roller to transfer your artwork onto the custom shirt.

- Let the paint dry, and enjoy the finished shirt with a truly one-of-a-kind design.

Tools and required: Cardboard, shirt, fabric paint, paintbrush, or roller.

Make it happen today!

How to make graphic tees at home

No matter which printing method you choose, there are several things to consider before applying your own designs. From picking the right products to creating the artwork, let’s look at some tips and tricks on how to make shirts at home.

- Choose your materials wisely– The color, material, shape, size, stretchiness, and other factors can affect your final design.

- Placement matters – Explore the latest trends or experiment with different placements to find the perfect spot for the designs on your custom-printed t-shirts.

- Consider washability – When picking a printing method, make sure your chosen option can withstand multiple washes without damaging your design.

How to make your own shirts with Printify

Using Printify and Print on Demand is the easiest, cheapest way to make your own t-shirts.

All you need is a custom t-shirt design and a vision – Printify takes care of the rest. Our Partners print t-shirts and ship them worldwide on demand, eliminating upfront cost and order fulfillment hassles.

Sign up for Printify

Create an account to access our free and convenient print-on-demand platform. We offer over 1,000 products, including dozens of high-quality, popular t-shirt styles.

Pick a shirt from the Catalog

Our Catalog has t-shirts for every occasion, shape, taste, and style. Filter by the printing method, Print Provider, production location, print type, material, and other features to make the best choice for your next wardrobe staple.

Apply your design to the shirt

Once you pick a shirt, it’s time to get creative. Click Start designing and customize your artwork in our Product Creator (formerly known as Mockup Generator).

If you have the perfect design ready, upload it to the product and adjust it with scaling, cropping, and other handy features.

If you’re starting from scratch, take advantage of all the cool tools in the Product Creator.

- Add emojis

- Text in different fonts, colors, and languages.

- Create patterns with our pattern tool.

- Remove the background.

- Generate unique AI images

- Add different elements from our free graphics library.

Next, click Preview to see how the design will look in real life on high-quality t-shirt mockups. Click Save once you’re finished.

Order t-shirts for yourself

Go to the My products section and find the green button on the top-right corner that says Create order. Choose Sample and enter your shipping details to order a shirt.

How to start an online t-shirt business

If you want the world to enjoy your epic designs – sell them online!

The global t-shirt market is worth $45.52 billion in 2024 and continues growing. T-shirts are that one clothing item that never goes out of style – a worldwide sensation. So why not grab your cut of the profits with your own custom-print t-shirts?

Pick a niche and design your shirts

A niche is a group of people with a particular shared interest. Think of tropical bird enthusiasts or Gregorian chanting fans. Choosing a niche to sell to saves you from getting lost in the endless sea of competitor stores and designs.

Once your niche is loud and clear, do some research on social media, competitor stores, and online forums to find out what kinds of t-shirts your target audience really wants. This will make the design process go much smoother by removing the guesswork.

Connect a sales channel

Pick an eCommerce marketplace like Etsy and eBay, a platform like Shopify, or build your own website from scratch. Printify integrates with all the leading sales channels, making it quick and easy to create and manage t-shirt listings.

Set prices and product details

Set prices and profit margins through the My products page. Use the bulk editing tool to quickly update multiple listings at once.

Choose your product details and images strategically to attract more attention from shoppers. Use relevant keywords in titles and descriptions, take your own photos, or customize the mockups to attract attention and raise credibility as a seller.

Customize your storefront

Personalize your store’s aesthetic to match your brand, values, and designs. But don’t go overboard with splashy colors, annoying pop-ups, and other elements that can lead to a bad user experience.

Add About us and Contact pages to make your business look professional and trustworthy. List transparent return policies, place products into convenient categories, and ensure your store page is easy to understand and navigate.

Market your t-shirt business

No matter how good your products look and feel, people won’t find them easily without proper marketing. Here are some ways to increase traffic and spread the word about your brand to a global audience.

- Run paid ads. Dedicate some money to paid advertising, ensuring your offers land directly in front of your target customers.

- Do social media marketing. Create business accounts on social media channels like TikTok, Instagram, Facebook, and Pinterest. Post YouTube Shorts, Instagram Reels, photo carousels, and fun TikTok videos to display your custom t-shirts.

- Try offline marketing. Be your own brand ambassador and participate in fairs, pop-ups, and other events where people can get to know your t-shirts and brand up close.

FAQ: How to make shirts at home

Each printing technique requires different equipment, but some things overlap. For most methods, you’ll need t-shirts (either cotton, synthetic, or a blend), a printer, ink, transfer paper, and a heat press machine.

If you choose to make shirts with Print on Demand, all you’ll need is a computer with an internet connection, a bit of time, and some creativity.

The easiest and least expensive way to make your own t-shirt is with Print on Demand and Printify. Our platform is free and easy to use. Choose from our Catalog of custom t-shirts, add your design, and let the Print Provider handle production and shipping.

If you’re making t-shirts to sell, Print on Demand is definitely the cheapest. You don’t need any upfront investment, inventory, or designer skills. Sign up for Printify, create shirts with our free design tools, list them online, and pay for fulfillment only after a customer orders.

Absolutely! T-shirts are an all-time favorite wardrobe staple that people buy frequently. Printify offers integrations that make it easy to sell shirts on Amazon, Etsy, or other sales channels.

Here’s what you’ll need to make your own t-shirts based on your chosen printing method:

- For iron-on transfer – Inkjet printer, iron, transfer paper (light or dark), scissors, cotton t-shirts.

- Heat transfer vinyl method requires Vinyl cutter, heat press, HTV roll, weeding tools, and plain shirts (cotton, polyester, or blends for heat press printing).

- Direct-to-garment printing needs a DTG printer, heat press, transfer media, and water-based inks.

- Dye sublimation printing uses a Sublimation printer, sublimation paper, sublimation inks, heat press, and polyester shirts.

- For Print on Demand you’ll need a computer with internet access to design and order shirts through Printify.

- Screen printing requires a mesh screen, screen printing ink, a squeegee, stencil paper, blank shirt, and a knife.

Here’s how to make your own graphic tee with each printing method:

- Iron-on transfer – Print your design (mirrored for light shirts), cut it out, iron it onto the fabric using firm pressure, and peel off the paper after it cools.

- DTG – Print directly onto the shirt using a DTG printer, then use a heat press to set the ink.

- Heat transfer vinyl – Cut your design on vinyl, weed out excess material, and press it onto the shirt using a heat press.

- Sublimation t-shirt printing – Print your design on sublimation paper, then use a heat press to transfer it onto a polyester shirt.

- Print on Demand – Sign up for Printify, choose custom t-shirts for digital printing, and order without making a mess in your room and huge financial investments.

- Screen printing – Print your design stencil on transparent acetate film and put it on top of a mesh screen. Place the shirt under the screen and press the design onto the surface. Use a squeegee to spread ink over the surface of the shirt.

Yes, you can make a living by creating custom t-shirts. Printify lets you create and sell t-shirts without upfront costs, making it accessible to anyone with an internet connection.

Choose a niche market, create unique designs for digital printing, and market your custom t-shirts through eCommerce platforms like Shopify, Etsy, and Amazon to scale your business and earn a consistent income.

Note: Make sure your designs are original to avoid copyright infringement.

How to make a custom shirt: Conclusion

Whether you’re rocking the DIY spirit with iron-on transfers or taking on the challenge of professional-grade direct-to-garment printing, there’s a t-shirt printing method out there that’s perfect for you.

The quality of your tools can make all the difference, so invest in highly-rated equipment if you’re going the DIY route and print shirts at home. Or, if you’re looking for a hassle-free way to bring your designs to life, Print on Demand is your new best friend.

With just a few clicks, you can design shirts and have them printed and shipped directly to you or your customers, leaving you free to focus on what you do best – designing and marketing!