Make a shirt with Printify today

Whether you’re making a small batch or running a large-scale production, this guide breaks down the most popular types of shirt printing.

From colors and costs to durability on synthetic or natural fabrics, compare their strengths and pick the perfect printing technique for your needs. The wrong choice could mean faded prints, peeling designs, or poor-quality shirts, so we’re here to help.

Key takeaways

- There are eight popular t-shirt printing techniques, including screen printing, DTG, DTF, dye sublimation, and embroidery – each suited for specific designs, fabrics, and batch sizes.

- Every method has its advantages and drawbacks, such as screen printing’s durability but high setup costs, or DTG’s detailed prints but limited fabric compatibility.

- The right printing technique depends on the fabric. Dye sublimation works only on polyester, while DTF is versatile across different materials.

- Screen printing is ideal for bulk orders, DTG is great for intricate one-offs, and embroidery offers a premium look – so match the method to your needs.

- Printify lets you print and sell t-shirts without investing in equipment, making it an easy, risk-free way to start a custom apparel business.

8 Popular t-shirt printing techniques explained

Alright, let’s break it down. There are many techniques in the t-shirt printing industry, all suitable for different types of designs, fabrics, and production volumes.

We’ll explain how each shirt printing method works and what materials it’s best for. We’ll also cover the pros and cons so you can choose the perfect option for your next t-shirt printing project.

1. Screen printing

The most popular of t-shirt printing techniques, screen printing (or silkscreen printing) is the go-to for bold, durable designs.

This printing method involves a mesh screen, screen printing ink, and a squeegee for application. It’s a little messy, but the results are crisp, vibrant, and long-lasting.

- Fabrics: Works on cotton t-shirts, blends, and even some synthetic fabrics

- Designs: Best for bold, simple graphics (not great for complex designs)

- Batches: Ideal for bulk orders due to high setup costs

Here’s how the screen printing process works:

A stencil (or screen) is created for each color in the design. A squeegee is then used to push the ink through the screen onto the t-shirt, layer by layer. Once all layers are printed, a heat press cures the ink for maximum durability.

Pros:

- Extremely durable designs – won’t crack or fade

- Vibrant, high-quality prints

- Cost-effective for large batches

Cons:

- Not ideal for tricky designs with lots of colors

- High setup costs – not worth it for small orders

- Limited to smaller print areas

Findscreen printing alternatives for your needs.

2. Direct-to-garment printing (DTG)

If screen printing is the heavyweight champ for bulk orders, then DTG printing is the sleek, high-tech option for detailed prints and on-demand custom clothing, especially custom t-shirts.

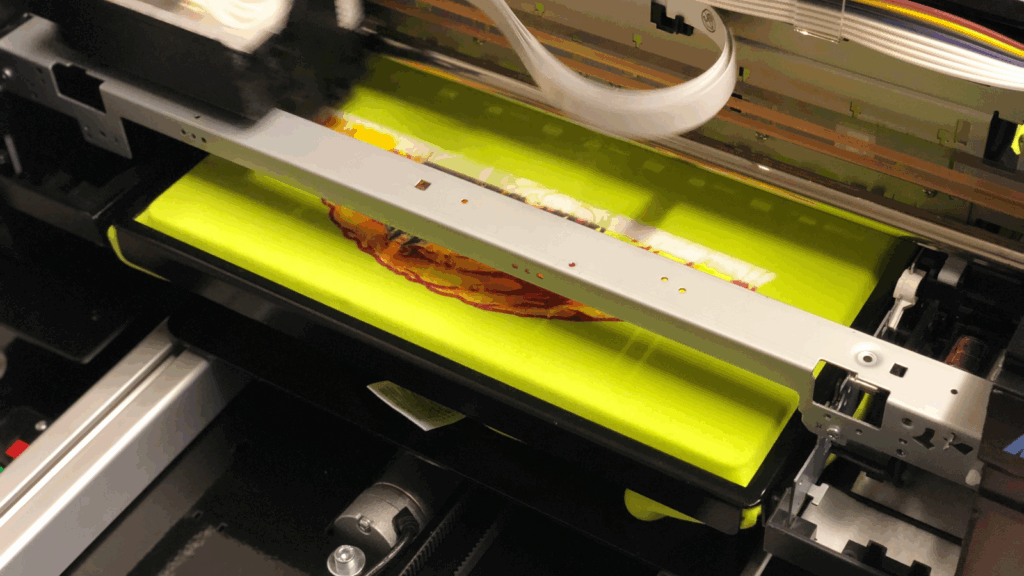

Direct-to-garment (DTG) printing works like a giant inkjet printer, spraying high-quality prints directly onto the fabric with precision.

- Fabrics: Works best on 100% cotton and cotton blends

- Designs: Perfect for intricate, tricky designs and photorealistic images

- Batches: Best for small orders or one-offs due to low setup costs

Here’s how direct-to-garment printing works:

Load a t-shirt onto a specialized DTG printer, pre-treat it to help the ink stick, and then print the design – just like printing on paper. A quick pass through a heat press and your design is locked in.

Pros:

- Full-color, high-quality prints

- Great for detailed artwork and complex designs

- Soft, seamless feel – no thick layers of ink

Cons:

- Best on cotton shirts – not great for synthetic fabrics

- Not as durable as screen printing – fades over time

- Slower for large orders compared to screen printing

See our article on DTG vs screen printing for a thorough comparison of both printing techniques.

3. Dye sublimation or all-over printing (AOP)

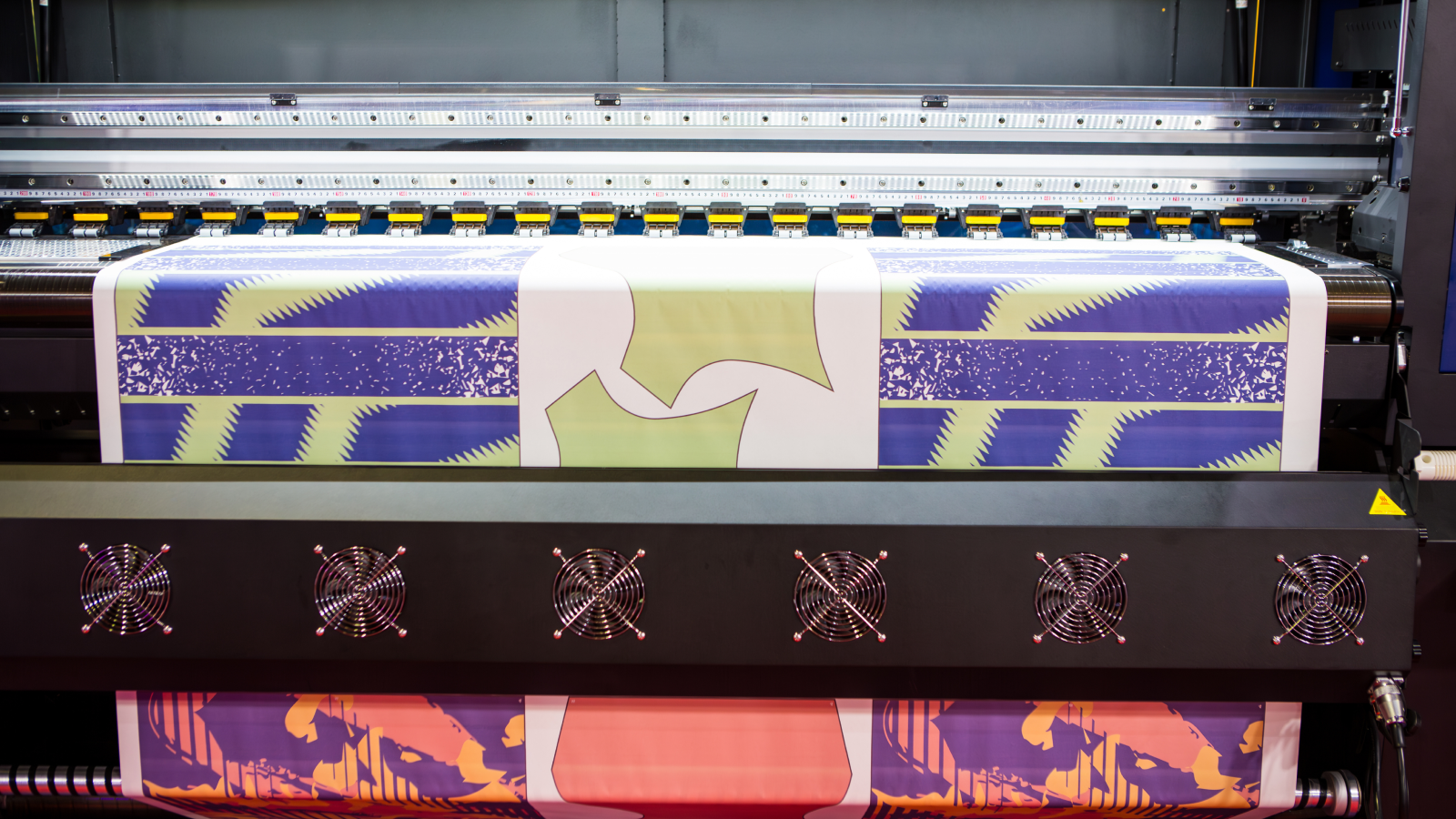

Want a seam-to-seam masterpiece? Dye sublimation or all-over printing (AOP) is the ultimate printing method for full-coverage, vivid results.

This printing technique uses heat to turn sublimation ink into gas, permanently bonding with synthetic fabrics.

- Fabrics: Only works on light-colored polyester

- Designs: Perfect for seam-to-seam printing and vibrant, full-color designs

- Batches: Great for custom, one-off shirts or small runs

Here’s how the dye sublimation printing process works:

Designs are digitally printed onto transfer paper using a sublimation printer. The paper is then placed on a polyester t-shirt and pressed with heat, infusing the ink into the fabric for a soft, permanent print.

Pros:

- Long-lasting, fade-proof prints

- Feels soft with no texture

- Ideal for patterns

Cons:

- Doesn’t work on cotton t-shirts

- Best for light fabrics – dark shirts don’t print well

- Higher cost compared to other printing techniques

4. Direct-to-film printing (DTF)

DTF printing is a modern take on t-shirt printing techniques. Unlike DTG, this heat transfer printing method doesn’t apply directly to fabric.

Instead, it transfers designs from a PET film onto the shirt. The result? Bright, bold prints that work on any fabric.

- Fabrics: Works on cotton, polyester, and blends

- Designs: Great for bright, intricate designs with solid colors

- Batches: Good for small-to-medium orders

Here’s how the DTF t-shirt printing method works:

Designs are printed onto a PET transfer film with special DTF inks. The film is coated with adhesive powder, heat-cured, and then pressed onto a t-shirt. The heat press melts the adhesive, bonding the design to the fabric.

Pros:

- Versatile for any materials, including synthetic fabrics

- Vibrant colors with high contrast

- No pretreatment required like DTG printing

Cons:

- Feels plasticky compared to DTG printing

- More steps than other heat transfer printing methods

- Best for smaller designs – not ideal for all-over printing

See DTF vs DTG printing for a full comparison.

5. Plastisol transfers

This heat transfer printing method combines the durability of screen printing with the flexibility of heat press printing.

Due to its long-lasting, vibrant prints, plastisol transfers are popular for custom jerseys,work uniforms, and promotional t-shirts.

- Fabrics: Works on cotton t-shirts, blends, and some synthetics

- Designs: Ideal for solid-color prints with bold shapes

- Batches: Great for small-to-medium orders, especially for team uniforms

Here’s how this heat transfer printing works:

Designs are screen printed onto plastisol transfer paper using plastisol ink. The printed sheet is then placed on the t-shirt and heat-pressed at high temperatures. This process bonds the ink to the fabric, creating a durable and crack-resistant print.

Pros:

- Durable, long-lasting designs

- Allows for glossy or textured finishes

- Works well for batch printing with minor customizations (like names, numbers)

Cons:

- Not ideal for photo-realistic or intricate designs

- Each design requires transfer paper, adding to costs for large batches

- Can feel slightly thicker on fabric compared to DTG printing

6. CAD heat transfer vinyl printing

Ever noticed the player names and numbers on sports jerseys? That’s CAD heat transfer vinyl printing at work.

This method uses heat press printing and precision cutting to apply designs made from colored vinyl sheets. It’s best for logos, letters, and simple shapes.

- Fabrics: Works on cotton, polyester, and blends

- Designs: Best for logos, text, and simple graphics

- Batches: Ideal for sports teams and custom names or numbers

Here’s how vinyl printing works:

A CAD cutting machine precisely slices heat transfer vinyl into shapes or text. The vinyl pieces are then pressed onto a t-shirt with heat, bonding them to the fabric. Since this process uses no ink, the print is bold and solid with a textured finish.

Pros:

- Crisp, professional-looking prints

- Works on any fabric

- Perfect for sports jerseys and work uniforms

Cons:

- Can’t print photo-realistic or gradient designs

- Takes longer due to precise cutting

- The print has a stiffer, textured feel compared to DTG printing

7. Embroidery

Embroidery gives a premium look for customizing t-shirts, polos, and hoodies.

Instead of printing, this method stitches the design directly into the fabric using colored thread. It’s a popular choice for corporate wear, high-end branding, and long-lasting designs.

- Fabrics: Works best on thicker materials like cotton t-shirts, polos, and hoodies

- Designs: Ideal for logos, monograms, and simple graphics

- Batches: Great for corporate branding, uniforms, and merchandise

Here’s how embroidered shirt prints work:

A sewing machine follows a digital embroidery file to stitch the design into the t-shirt. The process creates a textured, raised finish that will last over time. Unlike heat transfer or DTG printing, embroidery doesn’t use ink – just thread.

Pros:

- Extremely durable – won’t fade, crack, or peel

- Elegant, professional look

- No heat press or ink needed – more eco-friendly

Cons:

- Not suitable for photo-realistic or intricate designs

- Higher cost compared to screen printing or DTG printing

- Limited color blending – solid thread colors only

See our article on embroidery vs screen printing to help you choose the right technique for your designs.

8. Discharge printing

Discharge printing is the sorcerer’s trick of all t-shirt printing options. Instead of adding ink, it removes color to reveal a lighter, natural shade underneath. It’s a go-to for soft prints on dark-colored cotton t-shirts.

- Fabrics: Works best on 100% cotton t-shirts

- Designs: Ideal for washed-out, vintage-style prints

- Batches: Best for medium-to-large orders due to its setup process

Here’s how discharge printing works:

A special discharge ink, often mixed with water-based inks, is applied to the t-shirt and heat-activated. Instead of layering on color like screen printing ink, it strips the dye from the fabric, leaving a faded, vintage effect.

Pros:

- Incredibly soft – no thick ink or plastic feel

- Durable, long-lasting designs that won’t crack or peel

- Perfect for dark t-shirts, where other printing methods struggle

Cons:

- Color results can be unpredictable – each t-shirt may vary slightly

- Not compatible with synthetic fabrics

- Uses stronger chemicals compared to water-based inks

Which t-shirt printing methods should you choose?

What is the best printing method for t-shirts? It all comes down to your fabric choice and design complexity – whether it’s a small logo, large graphic, or an intricate print.

Here’s a quick comparison:

| T-shirt printing technique | Quality | Print area | Design options | Durability | Speed | Volume | Cost |

|---|---|---|---|---|---|---|---|

| Direct-to-garment (DTG) | Photorealistic, detailed | Standard size on chest and back | Complex, colorful designs | Lasts ~50 washes (more with proper care) | Slow (pretreatment required) | Small batches | Mid-range |

| Screen printing | Bold, solid colors | Standard size on chest and back | Simple designs | Extremely durable (100+ washes) | Fast once set up | Large orders (50+ shirts) | Lower for bulk |

| Dye sublimation | Bright, vibrant, seamless | Full shirt (seam-to-seam) | All-over prints, patterns | Extremely durable (ink bonds to fibers) | Medium speed (multiple steps) | Small-to-medium orders | Higher costs |

| Direct-to-film (DTF) | Vibrant, flexible prints | Standard size on chest and back | Intricate, bright designs | Long-lasting, slightly plasticky feel | Medium speed (film prep needed) | Small batches | Mid-range |

| Plastisol transfers | Bold, screen print-like | Standard size on chest and back | Shapes, solid-color prints | Highly durable (no cracking or fading) | Fast application, slow prep | Small-to-medium orders | Lower for bulk |

| Vinyl printing | Solid colors, sharp edges | Small to medium areas | Logos, numbers, and names on sports jerseys | Durable but stiff feel | Slow (cutting and weeding needed) | One-offs or small runs | Varies (depends on design complexity) |

| Embroidery | Raised, textured stitching | Small logos and text | Professional branding, premium look | Extremely durable (lifelong wear) | Slow (stitching process) | Small batches | Expensive |

| Discharge printing | Vintage, faded look | Standard size on chest and back | Soft prints on dark cotton shirts | Long-lasting, soft feel | Medium speed (chemical reaction needed) | Medium-to-large orders | Moderate to high (due to specialized process) |

Try multiple types of shirt printing with Print on Demand

Don’t want to invest in expensive equipment for your business? Print on Demandis a cost-effective and hassle-free way to create custom shirts without needing to operate your own printer.

With platforms like Printify, global Print Providers will handle printing, packing, and shipping for you.

We only print items after a customer orders, so there’s no upfront cost or leftover stock – perfect for selling custom products and starting a t-shirt printing business.

What different types of t-shirt printing methods are available with Printify?

Printify offers the following printing methods:

- Direct-to-garment printing (DTG)

- Dye sublimation printing (AOP)

- Direct-to-film printing (DTF)

- Embroidery

Try various t-shirt printing methods with no order minimums

Whether you’re launching a brand or just want a one-of-a-kind tee, you can do it all with Printify.

No order minimums mean no pressure and no need to pay for bulk production.

Need a single shirt for yourself? A few for a bridal party? Or a few hundred for a company event? Go for it – same great quality, zero restrictions.

How to create t-shirts with Printify

Sign up

To start printing t-shirts, register for a free Printify account.

Choose a product

Explore our Catalog of over 1,300 items, from t-shirts and hoodies to blankets and mugs. Select a Print Provider based on price, location, and other criteria, then click Start designing to go to the free Product Creator and customize your tees.

Add designs

Upload your design files or create new ones. Leverage our AI Image Generator, pattern tool, multi-language text editor, Shutterstock integration, and free graphics library. Preview your tees in high-quality mockups and click Save.

Edit and save the product

Adjust the design on the virtual product. Click Preview to see a life-like product mockup. When happy, click Save and proceed.

Order samples

On your Printify dashboard, order sample products of your brand-new shirts. Get one for yourself or use the sample to check the print quality before listing it on your online store.

If you want to save up to 20% on each product, sign up for Printify Premium.

Connect a store

Printify integrates with some of the most popular eCommerce platforms and marketplaces, like Etsy and Shopify. Connect the sales channel with your Printify account and start selling your custom tees.

Want to skip the hassle of using another sales platform? Create a Printify Pop-Up Store. Instantly sell products through a unique store link without any upfront costs or commissions.

Publish and start selling

Edit your product descriptions, set your prices, and start selling. You make the profits – we handle the logistics.

FAQ

It depends on your budget, design complexity, and order size. Screen printing is great for bulk, DTG for complex prints, dye sublimation for polyester, and DTF for versatility.

If you want zero hassle, leverage Print on Demand for your t-shirt printing business – easily sell your own t-shirts without handling printing or shipping.

Shirt printing techniques include screen printing, DTG, dye sublimation, DTF, heat transfer, vinyl printing, plastisol transfers, and embroidery.

Each method has unique strengths – some excel in durability, others in detail or affordability. Choosing the right one depends on your fabric, design, and production scale.

The six main t-shirt printing methods are:

- Screen printing: Best for bulk orders

- DTG (direct-to-garment): Great for detailed artwork

- Dye sublimation: Perfect for all-over prints on polyester

- DTF (direct-to-film): Works on most fabrics

- Heat transfer (includes vinyl and plastisol): Flexible but varies in durability

- Embroidery: Long-lasting and with a premium finish

There’s no single best t-shirt printing method – it depends on your needs. Screen printing is best for bulk orders, DTG for intricate designs, dye sublimation for polyester shirts, and DTF for versatility with most fabrics.

Screen printing, embroidery, and dye sublimation offer the most durable results. Screen printing ink sits deep in the fabric, embroidery won’t crack or fade, and sublimation printing fuses ink into polyester fibers, making it virtually permanent.

DTF and heat transfers can last, but quality depends on the fabric.

Printing with heat transfer paper is the most affordable DIY option, perfect for small batches. For bulk orders, screen printing offers the best cost per print.

If you want a risk-free, zero-investment solution, Print on Demand lets you sell custom shirts without buying equipment or stock – the Print Provider does it for you. That way, you can use different printing methods depending on your product and needs.

Final thoughts

Feeling inspired? Unleash your creativity and start your own clothing line! Whether it’s sublimation for unique designs, heat transfer vinyl for team shirts, or conventional screen printing, the choice is yours.

Embrace the ease of Print on Demand to print t-shirts and sell them worldwide. Now that you know your printing options, it’s time to bring your design ideas to life and start building a brand with Printify.