Create a custom shirt with Printify

Whether you’re new to direct-to-garment (DTG) technology or have been wearing DTG-printed clothing for a while, understanding this innovative printing method can be highly beneficial – especially when starting a print-on-demand business.

In this article, we take a closer look at direct-to-garment printing – its strengths and weaknesses, how it works, and which fabric is the best to print on.

We also provide some practical tips for creating a successful direct-to-garment design and explore some of the best print-on-demand products that are the perfect canvas for DTG printing.

Key takeaways

- High-quality designs made easy: DTG printing offers unmatched detail and vibrant colors, making it ideal for bringing your creative vision to life on custom t-shirts and apparel.

- Perfect for small businesses and on-demand printing: With no minimum order requirements, DTG printing is meant for entrepreneurs and artists who want to print small batches or test new designs.

- Eco-friendly and sustainable: Unlike traditional printing methods, DTG uses water-based inks and minimizes waste, making it a more environmentally friendly choice.

- Versatility on fabrics: While DTG printing works best on natural fabrics like cotton, technological advancements allow for customization on a wider range of materials, offering greater flexibility for your project.

What is DTG printing?

![What Is DTG Printing Direct-to-garment printing: A quick guide ([bp_year]) 1](https://printify.com/wp-content/uploads/2024/09/What-Is-DTG-Printing.jpg)

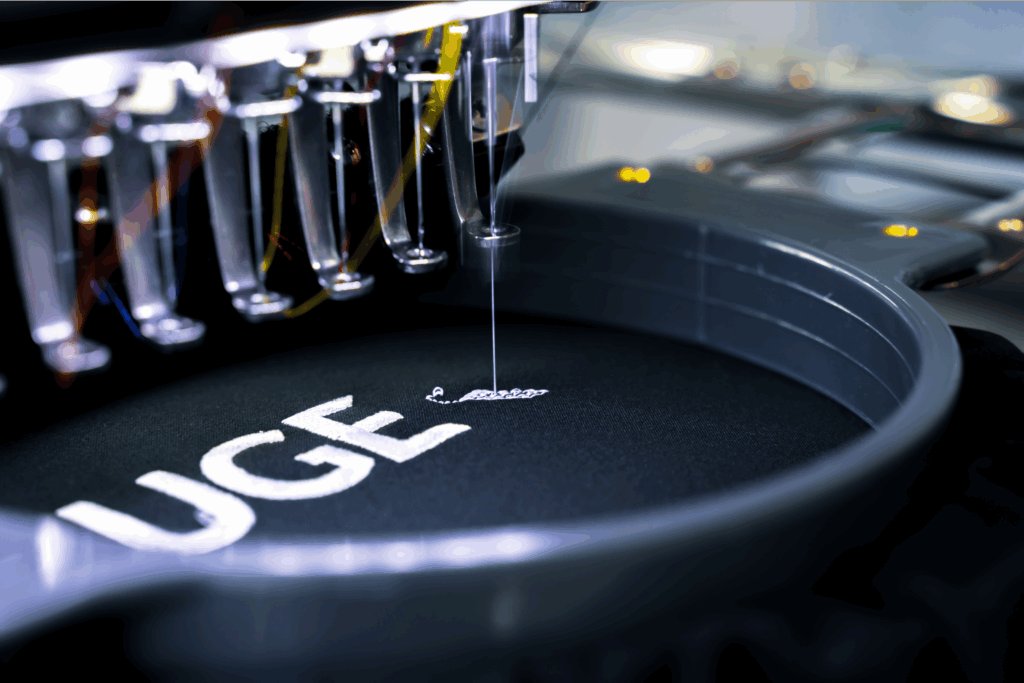

Direct-to-garment (DTG) is a printing process that uses modified inkjet technology to spray water-based inks onto apparel. It allows for intricate full-color designs with minimal setup. Unlike screen printing, the DTG process requires minimal setup time and is less labor-intensive, making it ideal for small-quantity orders.

As a cost-effective way to create detailed designs, DTG is a go-to printing method for many businesses and entrepreneurs worldwide.

The cherry on top? There are no order minimums, allowing people to order as few or as many products as they like.

How does DTG printing work?

![How Does DTG Printing Work Direct-to-garment printing: A quick guide ([bp_year]) 2](https://printify.com/wp-content/uploads/2024/09/How-Does-DTG-Printing-Work.jpg)

Although DTG printers and their models may vary, a few basic steps should always be followed when it comes to the DTG printing process.

Pre-Treatment Process

Pretreatment for DTG shirt printing is essential. With it, multi color designs in DTG inks are going to adhere better to the garment. On top of that, it’ll prevent the ink from washing off and enhance the vibrancy of colors.

Here are two ways it’s applied:

- Hand spraying. Involves manually pre-treating with a sprayer, which should be done as evenly as possible, using a smooth back-and-forth motion.

- Pre-treatment machine. A device that you put your shirt into and have it pre-treated automatically.

Printing Process

After the pre-treatment has dried, it’s time to place the garment in the DTG printer and begin the digital printing.

All garments – except white ones – have a white underbase applied first to enhance the vibrancy of the final print.

As soon as the underbase is printed, the DTG printer adds the rest of the colors. Like an inkjet printer, it uses a mix of cyan, magenta, yellow, and black.

Curing Process

When the DTG shirt is printed, it needs to dry for the final time to cure the ink. This helps the garments resist washing and prevent dulling after just a few washes.

Here are two ways DTG-printed apparel can be cured:

- Conveyor dryer. Typically, most industrial manufacturers cure ink using a conveyor dryer.

- Heat press. A good option for small businesses with only a few products to cure. If there are more, it becomes a rather labor-intensive and time-consuming endeavor.

DTG printing: Pros and cons

![DTG Printing Pros and Cons Direct-to-garment printing: A quick guide ([bp_year]) 3](https://printify.com/wp-content/uploads/2024/09/DTG-Printing-Pros-and-Cons.jpg)

When it comes to printing for profit, it’s no surprise that DTG has become the preferred choice among entrepreneurs, artists, and other creatives.

However, to get the full picture and better understand digital printing, let’s look at some of its strengths and weaknesses.

Pros:

- High-detail image quality, unlimited colors. DTG prints are exceptional in their quality. This method can recreate intricate designs in the full spectrum of colors, resulting in very detailed and high-quality prints.

- No minimum order quantity. With DTG printing, order as few or as many products as you like. DTG printers offer a cost-effective way to print products on demand.

- Environmentally friendly. Today’s technology has paved the way for using environmentally-friendly inks, and the process is highly energy-efficient.

Although DTG machines have revolutionized the apparel industry, they also have some disadvantages.

Cons:

- Doesn’t work on every textile. Although it depends on the garment printer, blanks used for DTG printing should ideally contain at least 50% cotton to enhance absorption and improve print quality. That said, technology is advancing quickly and digital printing on a polyester textile is no longer a distant dream.

- Limited application surfaces. Unlike sublimation printing, which allows all-over-prints, DTG print surfaces can be limiting. Additional print areas require a lot more manual setup.

- Not optimal for bulk orders. DTG printing is slower than other printing methods. However, it’s ideal for print-on-demand and eCommerce businesses – easily print a few shirts and still make a profit.

Make it happen today!

Best fabrics for DTG printing (with product examples)

![Best Fabrics for DTG Printing Direct-to-garment printing: A quick guide ([bp_year]) 4](https://printify.com/wp-content/uploads/2024/09/Best-Fabrics-for-DTG-Printing.jpg)

Since DTG printers use water-based ink, natural fabrics produce the best results. They absorb ink well, creating vivid colors printed directly onto the garment.

These are the most suitable textiles for DTG:

- Cotton

- Ring-spun cotton

- Combed and ring-spun cotton

- Organic cotton

- Linen, other natural textiles

Unleash your creativity with the power of direct-to-garment t-shirt printing. Browse our wide range of products below and see how your designs can come to life on various apparel and accessories. From classic t-shirts to cozy custom hoodies, the possibilities are endless.

DTG vs screen printing

Choosing the right printing methods for your custom apparel can be tricky. Here’s a quick breakdown of DTG and Screen Printing to help you decide.

Consider these factors before making your choice:

- Upfront investment

- Design complexity

- Product quantity

- Brand image

Here’s a table comparing DTG and Screen Printing:

| Feature | DTG printing | Screen printing |

|---|---|---|

| Quality | Unrivaled photorealistic prints. | Vibrant, high-quality prints. |

| Durability | Withstands over 50 washes. | Best choice for long-lasting garments. |

| Design complexity | Excellent for intricate designs. | Limited to simpler designs. |

| Sustainability | Water-based inks, energy-efficient. | Uses more water, possible overproduction. |

| Minimum order | Print as few as one. | Minimums typically 5-100 units. |

| Production time | Slower, best for small orders. | Faster for bulk orders after setup. |

| Cost | Affordable for small orders, not ideal for bulk. | Expensive for small orders, cost-effective for bulk. |

Key takeaways:

- DTG excels in high-quality, small-batch, detailed designs.

- Screen Printing is perfect for bulk orders, simpler designs, and maximum garment longevity.

Choose the printing method that best suits your business by considering your specific needs.

Compare DTG vs Screen Printing in detail on our blog.

Tips for your first DTG design

![Tips for Your First DTG Design Direct-to-garment printing: A quick guide ([bp_year]) 5](https://printify.com/wp-content/uploads/2024/09/Tips-for-Your-First-DTG-Design.jpg)

DTG printing allows great precision in image reproduction, meaning you can go as complex as you like regarding colors and details in your designs.

To create a great design, you should:

- Search for inspiration online. Draw inspiration from Amazon, Etsy, Pinterest, and many other sites to see what designs other people are selling.

- Provide high-resolution image quality. When creating designs for shirts or any other apparel, make sure you have a high-resolution image. This way, the DTG printer can create a clear, sharp, and colorful print.

The key is to make sure your designs are saved in the highest resolution possible for the best print quality.

- Ensure you follow the print file requirements to achieve the best DTG prints possible.

In the side panel of our Product Creator (formerly known as the Mockup Generator), view specific file requirements for each design area of the garment. Click here to learn more.

- Create mockups to view how your printed garments will look in real life.

After you’ve finished your design, our Product Creator allows you to preview the final product and create realistic mockups that you can use on your digital storefront.

Whatever your goals, always strive to connect your brand and your customers. If you’re interested in tips, tricks, and resources on how to create your first design, our recent article will come in handy.

Printify has created a library of free and print-ready designs to make it easier for you. These designs range from Mother’s Day to Halloween and include the most popular sale seasons, such as Christmas and St. Valentine’s day.

The best part is that these designs can be used on products immediately because they’re under a Creative Commons license for commercial use.

Frequently asked questions

Direct-to-garment (DTG) printing is a method that uses specialized inkjet technology to print designs directly onto garments. It’s like printing on paper, but on fabric! DTG printers use water-based inks that soak into the fibers for a smooth, high-quality finish.

It depends on your order quantity. DTG is generally more cost-effective for small orders (up to 25 shirts) because there’s minimal setup involved. Screen printing has lower per-unit costs for larger orders (more than 100 shirts) due to economies of scale, but requires upfront setup fees.

DTF (direct-to-film) printing involves printing designs onto a film transfer sheet first, then heat-pressing it onto the garment. DTG printing applies ink directly to the fabric. Here’s a quick comparison:

- DTG: Better for intricate designs and small orders. Offers a wider range of printable fabrics.

- DTF: Faster production for larger orders on specific fabrics (like nylon). May offer brighter colors on dark fabrics.

The main disadvantage of DTG is that it’s slower than screen printing for large orders. Additionally, DTG inks work best on natural fabrics like cotton. While possible on some synthetics, results may vary.

With proper care (washing inside-out on cold), DTG prints can withstand over 50 washes and maintain their quality.

The best method depends on your needs. Consider these factors:

- Order quantity: DTG is better for small orders, and screen printing for bulk.

- Design complexity: DTG excels at intricate designs, screen printing for simpler ones.

- Fabric type: DTG works best on natural fabrics, screen printing on a wider range.

- Turnaround time: DTG is slower for bulk orders, screen printing is faster once set up.

Closing thoughts

In the world of on-demand manufacturing, DTG printing remains unrivaled. If you’re just starting your entrepreneurial journey, DTG printing offers a hassle-free way to easily print one-of-a-kind products for your customers.

With many strengths, it’s the go-to printing method for print-on-demand entrepreneurs of all calibers. Here’s why:

- Cost-effective. No investment is required, and anyone can start printing today.

- High-detail print quality. With DTG, the entire design looks photorealistic.

- No minimum order quantity. Order as few or as many products as you wish.

- Environmentally-friendly. With eco-friendly inks, printing is more sustainable.

Whether you want to start a print on demand business, simply print something for yourself, or scale your existing venture, DTG printing offers something for everyone.