Start a custom printing business with Printify

With a history of vibrant serigraphs and bold renditions of celebrities, screen printing is a work of art that has moved into industrial use with as much success, but is it the right choice for you?

Printing methods for big batches or small details, vibrant prints or stitched designs, Printify has looked at them all, and we’re here to help you find the eight best alternatives to screen printing.

What is screen printing?

Screen printing, traditionally silk-screen printing, is the process of applying prints by transferring inks via stencil through a mesh screen. Silk screening is very versatile for large product batches and can be used to print on fabrics, paper, wood, and other hard decor materials.

The finished result depends on the selected screen and mesh count, the quality of inks used, the alignment of the press, and the final curing process by hand or via a heat press machine.

How is screen printing done?

Print artists start by selecting a screen and choosing a mesh count appropriate for the resolution of the graphic. They then coat the screen with an ultraviolet light reactive emulsion layer, which hardens the negative design area to create a blocking stencil.

Once done, designers start transferring on a flattened canvas by pressing the inks through the stencil with a squeegee blade. Then, after curing the surface under heat, the inks dry and permanently set. Artists can repeat this process using the same stencil with different colors.

Why look for alternatives?

The screen printing process is very flexible, but it might not be what you’re looking for in terms of design potential and setup. Here are the pros and cons of screen printing:

Pros:

- High volume use

While the setup process takes more steps than other methods, screen printing is considerably more cost-effective when working on bulk projects with the same design. - Material flexibility

Screen printing is adaptable with inks for both organic and synthetic fabrics, as well as paper, wood, ceramics, glass, metal, and plastic for various surface decals. - Print durability

The process applies a thick layer of ink that absorbs into the substrate, making it less likely for designs to fade away from light exposure or multiple wash cycles.

Cons:

- Long setup time

Screen printing is less suitable when working with multiple print designs in small batches due to the lengthy setup for each new screen and the application of different color stencils. - Quality limitations

Screen printing isn’t suitable for high-quality or photorealistic prints, especially when trying to achieve half-tones, shading, and delicate gradations. - Ink quantity control

Applying inks isn’t as precise as on a digital printer, which may cause imperfections, design bleeds, and raised prints, creating a bump in the texture.

With screen printing as the baseline, we can now move on to eight possible alternatives that can produce better results depending on your specialty or even offer new and exciting techniques.

Make it happen today!

8 Alternatives to screen printing

Direct-to-garment printing

DTG is a machine printing method that uses water-based inks to spray or jet the image directly on the garment’s surface. This digital alternative specializes in garment printing to produce photorealistic results with a thin coating and full-color layering.

Pros:

- High detail results:

DTG printing can achieve high-quality prints with intricate details due to the high precision control of the print equipment. - Quick setup time:

Working similarly to an inkjet printer, the DTG printing process doesn’t rely on stencils and takes less overall time to prepare. - Color accessibility:

Unlike screen printing, DTG applies prints from a digital file and can incorporate multiple colors in a single pass.

Cons:

- Material availability:

DTG’s water-based inks bond well with natural fabrics but don’t adhere to synthetics as effectively, limiting print item possibilities. - Slower turnaround:

Best used for smaller runs, direct-to-garment printing takes longer to manufacture in quantity due to a slower-set print speed. - Larger order costs:

In the long term, DTG inks and larger production runs are more expensive than screen printing.

Dye sublimation printing

Sublimation printing uses a specialized inkjet printer and dye-based inks that transform into gas under heat and bond with the substrate’s fibers, becoming a part of the garment for a durable end product. This is a common commercial method for vibrant polyester-based fabrics.

Pros:

- Superior colors:

The sublimation process is a popular technique for vivid color saturation with a wide spectrum of gradients and shades. - Longer lasting:

Since sublimation inks are suffused and bonded with the fabric, the product is more durable and won’t peel and fade. - No surface feel:

Sublimation printing doesn’t leave a physical coat on top of the substrate, making the final result as smooth as the original print blank.

Cons:

- Limited to polyester:

Dye sublimation can only be used on polyester-rich fabrics that open under pressure and bond efficiently. - Best for light substrates:

Sublimation dyes will not transfer on dark garments, producing the best visual results with white or lighter fabric materials. - Initial costs:

While easier to prepare in the long run, sublimation printing requires a larger investment in equipment and specialty inks.

Heat transfer printing

Heat transfer printing, also known as thermal printing, uses a special transfer sheet to imprint high-quality images directly on a substrate using a heat press. The sheet is made digitally with a transfer paper print or heat transfer vinyl material and pressed until it adheres to the garment.

Pros:

- Great for small runs:

A good alternative to screen printing for smaller print runs with a shorter setup than other heat-based digital printing methods. - Material versatility:

Well suited for a variety of fabrics like cotton and polyester, including other non-garment materials such as ceramics and metals. - High quality and color:

Can produce high-resolution images with complex textured designs and multiple colors, as long as different pigments don’t overlap.

Cons:

- Lack of durability:

More prone to peel or fade when exposed to high heat or friction, heat transfers are less durable than their screen printing alternatives. - Expensive for large batches:

Larger heat transfer print product quantities are more time-consuming and will result in higher overall production expenses. - Raised print layer:

Prints lay on top of the substrate, resulting in textured surfaces with a rubbery feel rather than absorbing and permeating the fabric.

Rhinestone transfers

Personalization with rhinestones is a stand-alone and unique method for decorating apparel. It uses a heated adhesive to bond with the substrate without needing expensive machinery. Rhinestones are a traditional staple for DIY accessories and luxury decals.

Pros:

- Fewer equipment costs:

No need for heavy machinery or inks – can be done at a hobby-level budget with a fast turnaround from simple tutorials online. - Independent design choice:

Designs are not subject to substrate dependencies, color requirements, or other limitations that might impact the choice of canvas. - Range of adaptive tools:

A rhinestone template and adhesive transfers can define design areas with high accuracy, making it much faster to reproduce in bulk.

Cons:

- Does not involve printing:

While a possible alternative for custom decals, this method can’t produce printed images like traditional screen printing. - Limited to accent features:

Rhinestone transfers are limited to simple lettering or silhouette designs and can’t reproduce complex or photorealistic images. - Subject to adhesive strength:

Lower-quality rhinestones are more likely to peel off against friction or fade in color, having to rely on a very delicate wash cycle.

Digital printing

Digital printing is any form of machine printing, such as inkjet or laser printing. Simply put, the key differences between this and other digital printing methods like DTG or Dye Sublimation are its machine and material versatility – pushing the digital printing industry forward in accessibility.

Pros:

- Range of application:

A digital printer or CMYK white toner printer works great on both light and dark garments, as well as paper, plastics, and other materials. - High-quality prints:

Digital prints are unmatched in quality, offering full-color printing at a much higher resolution than screen printing. - Quick setup time:

Since digital printing doesn’t require any additional setup for outlining and preparing stencils, the initial setup time is much faster.

Cons:

- Limited color matching:

Digital printing is not recommended when matching unique pantones and can vary in color based on the specific machine used. - Expensive for large batches:

Just like the other digital methods, expect much more detailed designs at a higher overall cost when producing in bulk. - Design placement:

Digital prints are constricted by their machine dimensions, while screen printing is easier to apply in complex locations on the print area.

Foil printing

Foil printing is coating a substrate with a thin metallic film with a glowing sheen (similar to gold leafing) to accent anything from paper and plastics to apparel. It uses a print toner as an adhesive for the foil, letting it attach under heat and integrate with the substrate.

Pros:

- Glossy reflective result:

The metallic foils produce a natural reflective glow that can’t be recreated with screen printing, even when using metallic-base dyes. - Material availability:

Considered a premium look for product packaging and paper, foil prints are also durable on fabrics and faux leather materials. - Environmentally sustainable:

Foil rolling is a dry process of simply applying heat, meaning it doesn’t produce harmful vapors or require multiple solvents and inks.

Cons:

- Design resolution:

Foil stamping can’t capture small lettering or complex details and is often considered a print finish to enhance other printing options. - Cost of resources:

Metallic rolling equipment isn’t that much more expensive, but layering detailed designs requires multiple runs at a higher cost. - Labor intensive:

Creating custom foil dyes, aligning the canvas, and ensuring proper adhesion takes more setup than traditional screen printing.

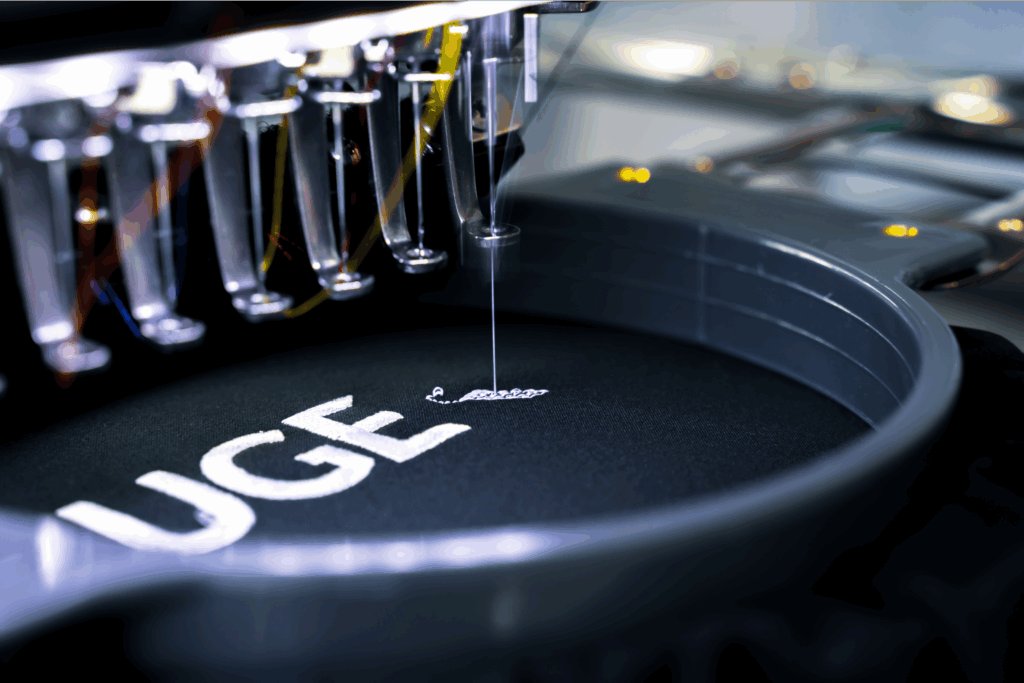

Embroidery

Embroidery is a great apparel design alternative for any luxury clothing line, set apart by a higher retail starting price due to the intricacy of the stitching process. A custom t-shirt business or designer will often use embroidery over other printing methods for quality branding options.

Pros:

- Unique tactile quality:

Enhances personalized designs, especially branding elements and initials, with a complex stitched or embossed look. - Strong durability:

Embroidery is the only option that doesn’t require additional adhesives or solvents to maintain a strong bond with the substrate. - Versatile materials:

The stitching method works for any woven, non-woven, and knitted garment, used primarily on thick-fabric apparel items.

Cons:

- Limited to simple designs:

Embroidery can’t produce complex designs as well as an ink printing method and is best suited for smaller decals and accents. - Longer production time:

The embroidery stitching process is more time-consuming than traditional printing methods, even with an embroidery machine. - Extra color expenses:

While some services provide unlimited color options, using distinct pantones can rack up material costs, especially in larger batches.

Applique

Applique is a specialty embroidery technique where manufacturers attach pre-cut fabric designs to a garment and stitch them along with a smooth satin thread. This method shares many of the associated advantages and disadvantages of embroidery but is faster and more flexible overall.

Pros:

- Larger design elements:

While embroidery is usually limited to accents, the applique method can produce fabrics for both large and small designs alike. - Faster turnaround:

Applique uses pre-cut design elements instead of full stitching, which means that decorating apparel takes less time. - Lower overall costs:

Rather than paying cost-per-stitch, applique is cheaper to manufacture and reproduce with the same smooth tactile results.

Cons:

- Less design complexity:

Applique is limited to simple design elements like large block lettering or clear color patterns, even more so than embroidery. - Lower durability:

There is a higher risk of unraveling or fraying under friction since the cut material is only stitched around the edges. - Stiff fabric surface:

Depending on the number of layers, applique can have a heavy surface feel that limits its use to thicker fabric garments.

Make it happen today!

Start a Print on Demand business with Printify

Try print on demand for free and experiment with the best screen printing alternatives from professional Print Provider services without paying for expensive hardware and storage.

Create designs from quality screen printing alternatives.

Select from our Catalog of hundreds of unique print items – t-shirts, hoodies, home decor, and more – and apply your designs digitally with our easy-to-use Product Creator (formerly known as the Mockup Generator).

Set up a store and start selling with print-on-demand.

Create a store on top eCommerce sales channels with our partnered integrations. We send all sold orders to your chosen Print Providers, who produce and ship products on your behalf.

To summarize

Decide on the best method for your needs from our list of eight alternatives to screen printing. Whether you prioritize pinpoint accuracy, fast turnaround times with various substrates, or are looking for something entirely different, each option provides distinct advantages and specialized features.