Start your custom printing business today!

What is the difference between die-cut and kiss-cut? Find out and select the right sticker material and style for you by comparing both types.

We’ll go through the cutting process, peel and backing types, and pricing to help you understand the benefits of using kiss-cut vs die-cut stickers.

What is a kiss-cut sticker?

Kiss-cutting means the sticker’s shape is cut through the vinyl, but the paper backing stays intact. This allows for easier peeling and handling.

Kiss-cut stickers are ideal for promotional giveaways and packaging seals, offering a user-friendly and versatile option for various applications.

Their easy peel-off backing makes them perfect for people and businesses looking for convenience and precision in their sticker applications.

How are custom kiss-cut stickers made?

Kiss-cutting involves vinyl and cutting equipment. Here are the steps:

- Design creation. Make your sticker designs using graphic design software.

- Printing. Print the design onto a sheet of vinyl.

- Kiss-cutting. Use a precision cutter to cut through the vinyl layer, leaving the paper backing intact.

- Weeding. Remove the excess vinyl around the sticker.

And that’s it! Your kiss-cut stickers are good to go.

You can also expand your storefront by designing custom bumper stickers to appeal to commuters and beyond.

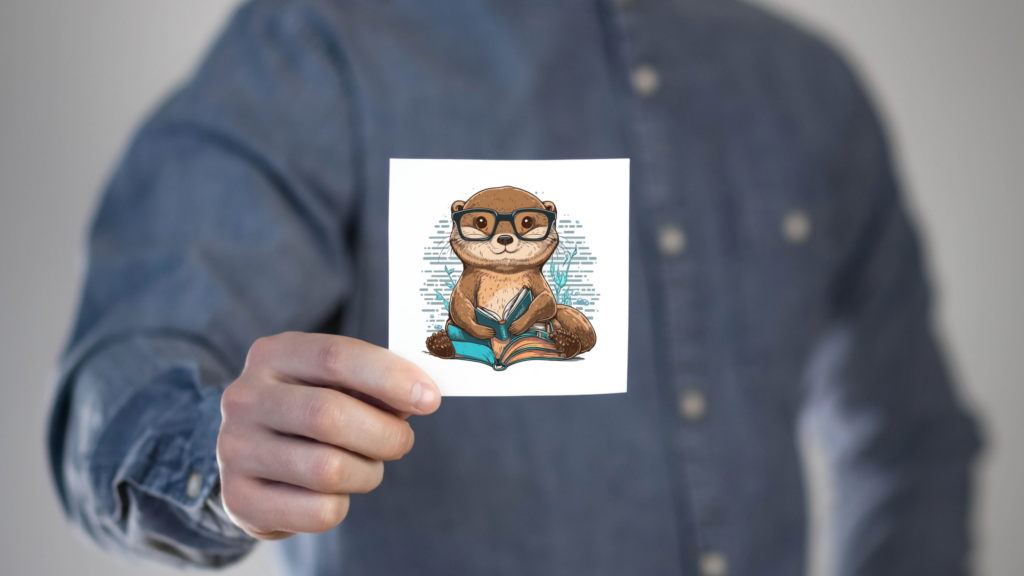

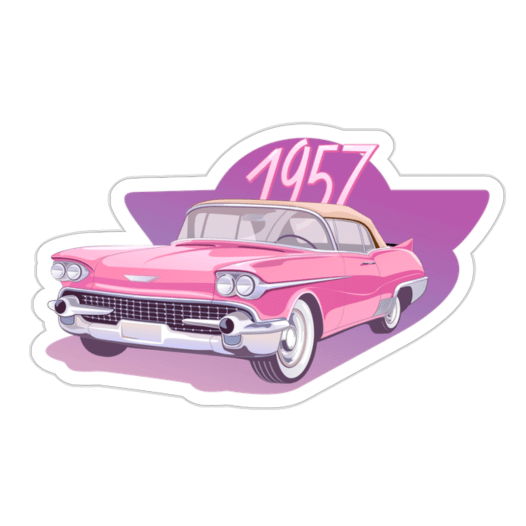

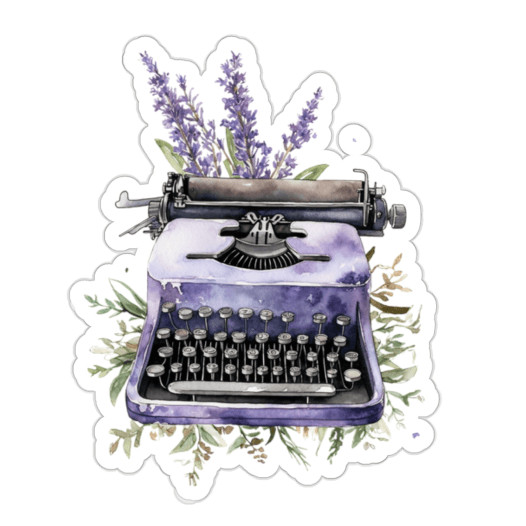

Examples

These kiss-cut stickers are versatile for various uses, including packaging, branding, and giveaways. Explore our selection of high-quality kiss-cut sticker designs to suit your needs.

Kiss-cutting benefits

Stickers made with kiss-cutting are versatile, durable, and highly practical.

Want intricate designs? No problem. These stickers can handle everything from delicate designs to bold, eye-popping creations in any color – even holographic tones that shimmer.

Made from high-quality, fade-resistant vinyl, kiss-cut stickers generally don’t scratch or tear. They’re also easy to peel and stick onto paper, glass, plastic, or metal.

What’s more – they’re budget-friendly! Compared to big-ticket promo merch like t-shirts, kiss-cutting lets your brand shine while being easy on your wallet.

What is a die-cut sticker?

With die-cutting, the sticker has the vinyl and paper backing cut right through.

Unlike kiss-cut stickers, die-cut stickers are cut precisely to the shape of the image, leaving only the sticker design without any excess material.

These stickers are best for custom shapes and standout visuals, making them ideal for branding, promotions, and personalizing products or gifts.

How are die-cut stickers made?

For this, you’ll need a vinyl material and cutting equipment. These four steps outline how to make stickers with a die-cutting process:

- Design creation. Make or select a custom design using graphic design software.

- Printing. Print the design onto a sheet of vinyl using high-quality printers.

- Die-cutting. Use a die-cutting machine to cut through the vinyl and backing layer, following the precise design shape.

- Weeding. Remove any excess material around the cut design.

And just like that, your custom die-cut stickers come out in the desired shape.

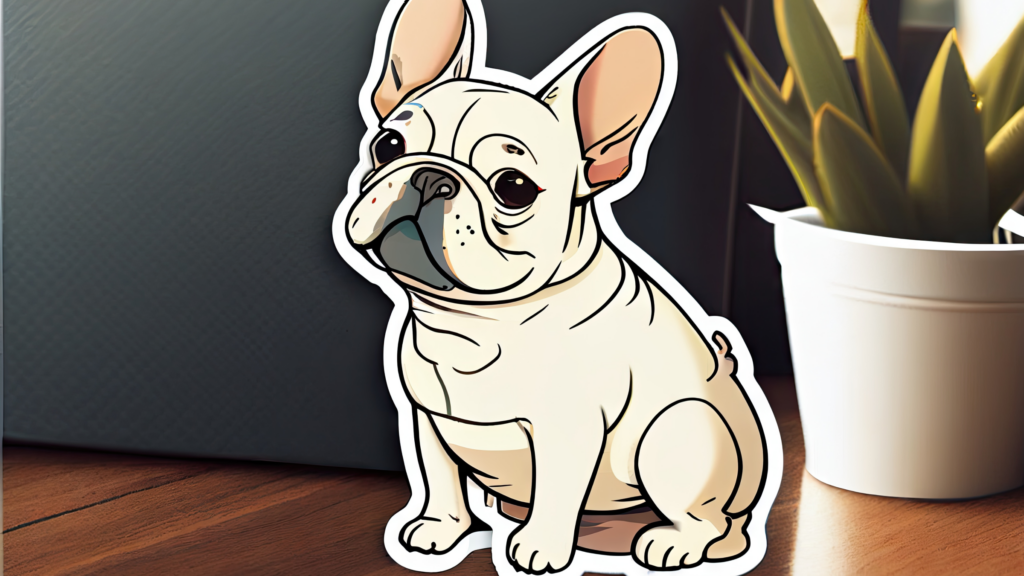

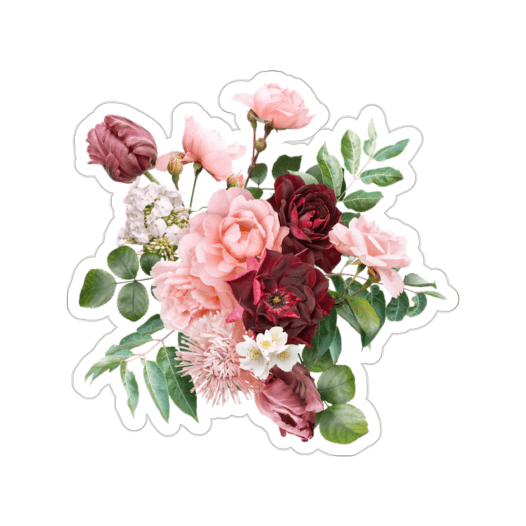

Die-cutting examples

Stickers made with die-cutting produce a sleek, custom shape perfect for branding, gifts, and creative projects. Browse our selection to find designs that stand out.

Die-cut sticker benefits

Die-cutting is the way to go to make a statement. Cut to match your design’s exact shape, these stickers are the perfect custom product to leave an impression.

Want a sleek logo or a funky design bursting with color? Die-cut stickers give your brand that distinctive edge to stand out.

Crafted from tough, scratch-resistant vinyl, die-cut stickers last. Aside from paper, glass, plastic, or metal, die-cuts can stick to lightly textured surfaces like tumblers.

What’s the difference between die-cut and kiss-cut stickers?

The main difference between kiss-cut and die-cut stickers is the depth of the cut.

Die-cut stickers are cut through both the vinyl and the backing paper, matching the exact shape of the design.

Kiss-cutting only cuts through the vinyl, leaving the backing paper intact to create a border around the sticker.

While kiss-cut stickers are easier to peel off and are great for sticker sheets, die-cut stickers are ideal for standalone designs and unique shapes.

Make it happen today!

Which one should you choose – Kiss-cut sticker vs die-cut

Is die-cut or kiss-cut better? They vary in a few ways, including versatility, durability, and ease of application.

Die-cut and kiss-cut stickers have their own pros and cons, so choose based on your intended use and need when starting your sticker business.

| Kiss-cut stickers | Die-cut stickers | |

|---|---|---|

| Price | Cheaper with a simple manufacturing process involving less cutting. | More expensive due to the cutting process complexity. |

| Peelability | Easy to peel since the paper backing stays intact. | Less easy to peel due to the exact edges of the die-cut stickers. |

| Quality | High-quality stickers with extra backing but less precise edges. | High-quality custom stickers in more intricate shapes. |

| Durability | Less durable and can be prone to frayed edges. | Can withstand sun exposure and fading for a couple of years. |

| Cutting method | Only the top layer of the sticker is cut, leaving the backing paper intact. | The paper backing is cut into a specific shape together with the sticker. |

| Order quantity | Available in single pieces and sticker sheets. | Cut precisely into one custom-shaped sticker. Also available in sticker sheets. |

| Shape options | The shape of your kiss-cut stickers depends on your design. | A die-cut sticker can be made and cut into any custom shape. |

| Recommended use cases | Labels and logo stickers with simple designs. | Eye-catching designs for branding with unique shapes. |

| Production speed | Fast production due to the simple cutting process. | Slightly longer production to cut custom shapes through the vinyl and backing paper. |

| Sheet utilization | Kiss-cut stickers have extra backing paper for branding or additional information. | Die-cut stickers don’t have extra material to utilize for branding. |

| Surface types | Ideal for flat and smooth surfaces such as glass, plastic, and paper. | Suitable for uneven and textured surfaces like bikes or water bottles. |

From this list, we can see both die-cutting vs kiss-cutting are great but serve different purposes.

While custom die-cut stickers provide extra style, shapes, and customization with no excess material, they take longer to make and are harder to peel.

Kiss-cuts come in sheets for easy peeling, are more cost-effective, and provide extra backing paper for additional branding but are slightly less durable.

Now that you know the difference between die-cut vs kiss-cut stickers, find out how to make your own stickers to sell with Printify.

Custom sticker design ideas

Explore these creative design ideas for custom stickers. Whether for branding, promotions, or unique gifts, take inspiration from these examples to make die-cuts or kiss-cutting stickers that stand out.

Design ideas for kiss-cut stickers

Nature elements

Minimalist icons

Quotes

Travel

Food and drinks

Animals

Vintage nostalgia

Design ideas for die-cut stickers

Flowers

Puzzle pieces

Magical creatures

Unique niches

Learn more about selling stickers on Etsy to skyrocket your sticker sales with custom designs.

Sticker design tips

- Use high-quality designs – Make sure your sticker results come out perfect with no blurring or grainy effect.

- Choose the right colors – Select shades that align with your brand’s identity or design theme, and consider how they’ll look on different surfaces.

- Consider material and finish – Glossy finishes add vibrancy and shine, while a matte vinyl layer creates a sleek, understated look.

- Optimize for small sizes – Test your design visibility by scaling it down to the size you plan to print, checking that the text and details remain clear.

- Play with borders – Experiment with border thickness and color to see what works best for a polished, professional finish.

FAQ: Die-cut vs kiss-cut stickers

During production, the machine’s blade makes a precise cut that “kisses” the top layer of the material, leaving the backing layer untouched. This delicate approach makes the sticker easy to peel while maintaining the integrity of the backing sheet.

Kiss-cut stickers have only the top layer cut, leaving the backing material intact.

This method allows for easy peeling and handling. Kiss-cuts are perfect for creating stickers with intricate designs, as the extra border on the backing protects the sticker edges.

Die-cutting involves creating a specific shape using a sharp metal die, similar to a cookie cutter.

This technique cuts all the way through the sticker layer and backing based on the design, making die-cut stickers ideal for branding and promotional materials due to their unique appearance.

The best sticker types depend on your needs. Die-cut stickers are great for bold designs shaped precisely to your artwork. Kiss-cut stickers are easier to peel, protecting intricate designs and making them ideal for packaging or branding.

Kiss-cut singles feature a contour cut around the sticker vinyl, leaving the backing material intact. Die-cut singles are precisely cut through both the sticker material and backing, resulting in a unique shape and professional appearance.

Kiss-cut designs are often cheaper than die-cut. It has a simpler cutting technique that reduces potential waste, ideal for budget-friendly projects. However, the overall cost still depends on factors like your sticker size and order quantity.

Make custom stickers with Printify!

Now that you know the main differences between what is kiss-cut vs die-cut, their benefits, processes, and applications in more detail, you can make an informed decision that best suits your business needs.

Design and print top-quality custom-shaped stickers easily by leveraging Printify. Get started for free and tap into automated fufillment for endless profit opportunities.