Start a custom printing business with Printify

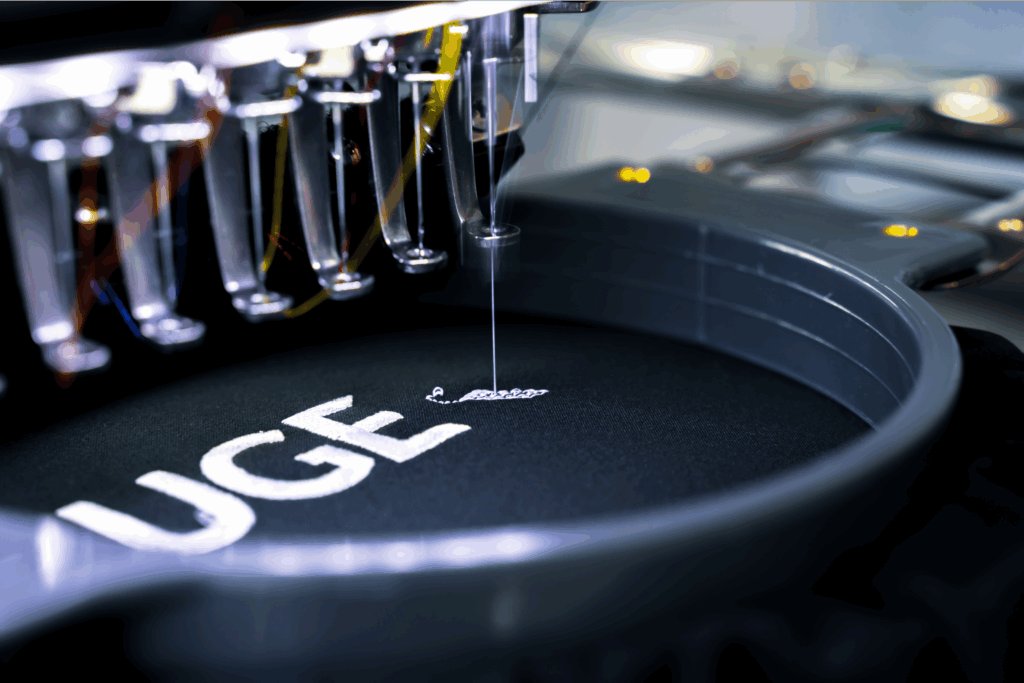

Direct-to-film (DTF) and sublimation printing make creating high-quality prints on diverse materials easier than ever. Gone are the days of flimsy prints that peel or rub away after a few uses!

These printing techniques are a game-changer in Print on Demand (POD), empowering people to customize products like t-shirts and home decor effortlessly.

In this article, we’ll break down the differences between DTF vs sublimation, explain their strengths, and help you decide the best fit for your printing business.

This post may contain affiliate links, which means we may earn a commission if you make a purchase through those links. This comes at no additional cost to you.

Key takeaways

- Printify offers products compatible with sublimation and direct-to-film printing.

- Each printing method caters to different designs and business goals.

- DTF printing works on many materials like cotton and synthetic blends, making it perfect for t-shirts and more.

- Sublimation excels in high-quality prints on light-colored polyester and hard surfaces.

- Each method uses different materials for printing transfers. DTF uses adhesive films, while sublimation embeds ink into polyester fibers.

- DTF is faster and ideal for on-demand orders, while sublimation printing requires additional setup time.

What is DTF printing?

DTF applies designs onto textiles using a polyethylene terephthalate (PET) transfer film, adhesive powder, and a heat press process.

This direct printing method simplifies traditional screen printing, providing a flexible solution for diverse applications.

Here’s how the DTF printing process works:

- Print the design onto PET film using DTF printers.

- Apply powdered adhesive to the printed design while it’s still wet.

- Transfer the design onto the fabric using a heat press machine.

What is DTF used for?

This printing technique is typically used for textile items like t-shirts and hoodies. It produces vibrant colors and sharp details on light-colored and dark-colored fabrics, including textured surfaces.

Direct-to-film printing works seamlessly with natural fibers, cotton blends, and polyester. Its versatile fabric compatibility has made it a favorite in the printing industry.

Check out our detailed guide to DTF printing for more information.

What is sublimation printing?

Sublimation, also called all-over print (AOP), is a widely used printing method that transforms ink into gas through heat, which bonds directly with synthetic fibers.

By embedding the ink into the material, sublimation creates permanent, high-quality prints.

Here’s how the sublimation printing process works:

- Print the design onto dedicated sublimation paper using specialized inkjet printers.

- Place the printed paper on the surface.

- Use a heat press machine to transfer the design. Heat and pressure infuse the sublimation ink into the material.

What is sublimation printing used for?

Sublimation works for photorealistic images, high color vibrancy, artwork with tiny details, and designs that require long-lasting durability.

Sublimation printing does not work on cotton or dark fabrics. However, it works exceptionally well on synthetic materials like white polyester fabrics and hard surfaces like mugs.

Read our glossary entry about sublimation printing.

What’s the difference between DTF and sublimation printing?

Both DTF printing and sublimation are popular techniques, each with its own unique strengths. Wondering, “Is DTF better than sublimation?” Well, it depends on the product you’re printing on.

Check out how these printing methods compare before choosing the perfect fit for your printing business.

| DTF printing | Sublimation printing | |

|---|---|---|

| Quality | Sharp, opaque, detailed prints on various fabrics, including cotton. | Smooth, vibrant, all-over prints infused into polyester fibers or hard surfaces. |

| Durability | Medium durability. Designs may crack or peel over time. | Highly durable. Ink bonds with fabric fibers, resisting heavy use. |

| Design complexity | Prints intricate, multi-color designs, even on dark fabrics. | Excels with vibrant designs on light-colored polyester but not on dark materials. |

| Sustainability | Less eco-friendly – uses plastic films and generates waste. | More sustainable – uses water-based inks with minimal waste. |

| Item quantity | Great for one-off or small orders and requires minimal setup. | Best for larger orders to offset higher costs. |

| Production time | Quick and suitable for on-demand printing. | Longer due to preparation and transfer steps. |

| Average cost | Affordable setup and materials – budget-friendly. | Higher equipment and material costs – ideal for high-volume use. |

Quality

DTF and sublimation both deliver high-quality prints, but their processes are pretty different. The best choice often depends on the product material and the desired finish, as each method excels in specific areas.

DTF printing produces sharp, opaque prints that sit on top of the fabric.

On the other hand, sublimation printing infuses designs into fabric or material, achieving smooth prints with exceptional color vibrancy.

The final product quality depends on which materials and colors you print on. DTF printing works on natural and synthetic fabrics in various colors. Sublimation printing is perfect for light-colored polyester fabrics.

Durability

Washing frequency and garment type can affect how long DTF printing and sublimation last.

With DTF printing, designs may crack or peel over time but withstand multiple washes if properly cared for. These prints are more prone to wear on heavily used or stretched garments. Washing in cold water and turning garments inside out before putting them in the laundry will help preserve the DTF print quality.

On the flip side, sublimation prints retain their vibrant colors wash after wash. The ink bonds with the surface, making it long-lasting and resistant to fading.

Design complexity

Both printing methods handle intricate designs, but there are some limits. The type of material and design complexity often dictate which one will deliver the best results.

DTF printing excels in photorealistic images and designs with fine details, even on textured or dark materials.

Sublimation printing produces stunning results for vibrant and complex designs but only on light-colored fabrics, synthetic materials, and hard surfaces like ceramic mugs.

Discover everything you need to know about preparing your prints with our must-read design guide.

Sustainability

Sustainability differs significantly between these printing methods and is influenced by the materials used and the waste they produce.

DTF printing uses adhesive powder and printed film, generating more waste and relying on non-biodegradable materials.

Sublimation printing relies on sublimation ink and dedicated sublimation paper, which are more eco-friendly.

If your goal is to run an eco-friendly printing business, choose sublimation printing as it aligns better with sustainability goals.

Minimum order

Order flexibility is another key factor for any printing business. The ability to scale production depends on the options for handling different order sizes.

DTF printing is perfect for one-off custom designs or small batch orders with minimal setup.

Sublimation printing is best for medium to large-scale production to offset the cost of sublimation printers and materials.

If you focus on small, on-demand custom orders or testing new designs, choose DTF transfers. Sublimation printing is better suited for high-volume production.

Production time

Production time depends on printing process steps and can be a significant factor into which method is best for your business and order volume.

DTF printing involves fewer steps, making it faster for tight deadlines. It’s ideal for businesses handling personalized or on-demand orders.

However, with sublimation printing, the heat transfer process requires additional time for preparation, especially for large-scale production.

DTF offers a shorter turnaround time than sublimation printing for last-minute orders or small-batch customizations.

Average cost

These printing methods require different equipment and materials, leading to a cost difference.

DTF printing has lower initial costs with affordable DTF printers, adhesive powder, and transfer film.

Sublimation printing, however, requires a higher upfront investment in specialized inkjet printers, sublimation paper, and compatible surfaces.

When comparing DTF transfer vs sublimation in terms of pricing, those on a budget with lower order volumes should likely stick to DTF printing. But if you have a higher budget and plan on selling higher volumes, sublimation may be worth the price.

Popular DTF and sublimation products from our Catalog

Still deciding between direct-to-film vs sublimation? We’ll make it easier for you! Printify’s Product Catalog is full of fantastic, customizable items using the best printing techniques for your designs.

Browse through options like t-shirts, socks, blankets, and ceramic mugs and view their printing methods.

Sell DTF or sublimation products with Printify

Want to sell custom products without the hassle of printing and shipping? With Printify, it’s not just possible – it’s easy and fun!

Whether you’re a new entrepreneur or an established seller, Printify streamlines the entire process of selling custom products with DTF and sublimation printing.

1. Sign up

Register for a free Printify account to access our Catalog and suite of design tools.

2. Choose your products

Browse Printify’s Product Catalog, which has over 1,000 popular products at the best prices. Pick items that align with your brand, niche, and audience.

Use the Decoration method filter to select DTF or all-over-print (AOP) products.

3. Apply designs

Once you choose a product, click Start Designing. You’ll be directed to our easy-to-use Product Creator. Upload a pre-made design or create something from scratch with our text editor, pattern creator, AI Image Generator, and free graphics library.

You’ll be shown high-quality mockups to review the final result before selecting Save and listing the products in your online store.

4. Order for yourself or sell

There are no order limits! Once your products are ready, order a sample for yourself or list them in your online store. If you’d like to sell your creations in person, we offer shipping discounts on bulk orders.

Selling online is easy thanks to Printify’s integrations with top eCommerce platforms like Shopify, Etsy, and Amazon. Enjoy seamless listing and order management.

5. Let us do the rest

When a customer places an order in your eCommerce store, our network of Print Providers prints and ships the item directly to their doorsteps – wherever they are worldwide.

Automatic order fulfillment gives you time to focus on creating new designs, marketing, and growing your printing business.

FAQ

The choice between DTF vs sublimation depends on your needs. DTF printing is ideal for small-scale, on-demand printing and works on diverse materials, including cotton and dark fabrics.

Sublimation printing excels in high-resolution, vibrant, all-over-print designs on light-colored synthetic fibers and hard surfaces.

When it comes to durability, DTF printing and sublimation have some considerable differences.

Sublimation pros include ink bonding with the fabric fibers, making designs long-lasting and resistant to fading.

DTF printing is durable but may crack or peel over time, especially on garments that endure heavy use or frequent washing. Proper care, like using cold water and turning the garment inside out when washing, extends the life of DTF prints.

DTF printing produces waste from PET films and relies on non-biodegradable materials, making it less eco-friendly. Unlike sublimation, which uses water-based inks, DTF is less aligned with sustainability goals.

It may also result in cracking or peeling with heavy use, and its slightly raised finish might not appeal to customers preferring seamless prints.

No, sublimation printers are not designed for DTF printing. They use specialized sublimation inks and papers to heat transfer the designs onto synthetic fibers.

To start DTF printing, you’ll need a dedicated DTF printer that works with PET films, adhesive powder, and the appropriate ink for the process.

Summary

When comparing DTF vs sublimation, each method offers unique strengths.

DTF printing works well with materials like cotton and fabric blends, ideal for small-scale customizations. Sublimation printing shines for its vibrant, durable designs on light-colored polyester and hard surfaces.

Consider your business needs to choose the best method, and let Printify simplify the process.