Sublimation Specifics

Chapter 7

Sublimation Specifics

Sublimation Printing vs. DTG Printing

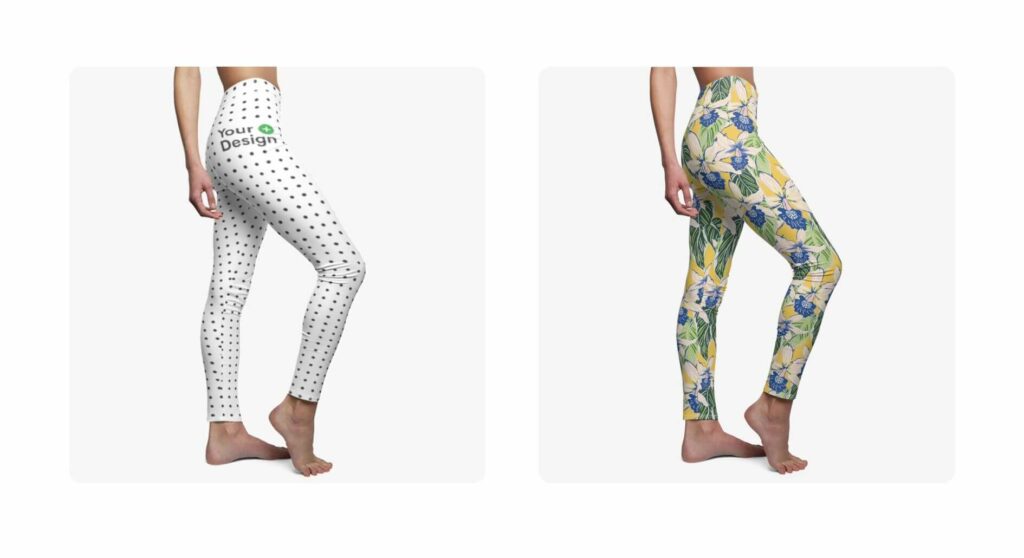

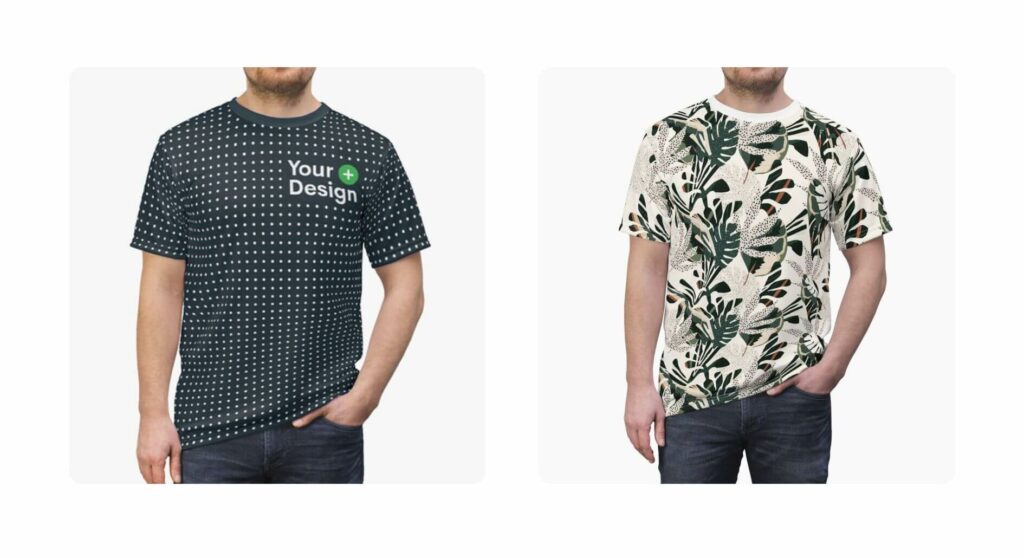

The major difference is that sublimation printing allows the entire garment to be used as a print area, whereas with DTG and DTF printing, you’re limited in the print area.

For example, some of our All-Over-Print products

How It Works

In sublimation, the ink moves from a solid to a gas state without ever being liquid. It’s a good printing method for polyester and hard-coated products. The ink is heated along with a transfer paper that allows it to become gas and spread throughout the fibers of the garment. The image itself will only deteriorate as the substrate does, making it a durable choice.

When to Choose Sublimation

Sublimation requires a polymer-based surface, so the process has its limitations and is best for polyester performance apparel or other hard-surfaced products. You can tell which products are sublimated in the catalog by looking for ones that say “All Over Print” or “AOP”.

AOP and Cut & Sew Limitations

Sublimation products are created, then have designs printed on them. Cut & sew products are the opposite: they’re printed, then stitched together. For this reason, an all-over-print design will seldom repeat perfectly – particularly along seams.

However, mockups are only digital representations, while the real design can slightly shift during the fulfillment process and cause a misaligned print.

Remember, that for some products (especially drinkware – mugs, tumblers, travel mugs) the seam line may still be visible even with a full-bleed design. For that, we strongly recommend avoiding wrap-around designs and artwork with important design elements placed near the edges (like repeating patterns, text messages, or large details).

If you’d like to explore the specifics of cut & sew capabilities, here’s a great guide. Or, see here for more AOP product limitations.

Don’t forget to utilize our Product Creator to its fullest extent when designing AOP products. To significantly reduce your time spent on AOP products, we’ve added a pattern creation tool, allowing you to design patterns from a single element. Forget outsourcing other programs or experts. Create your custom patterns directly on the Product Creator.