Print Colors

Chapter 3

Print Colors

The color spectrum used for printing is less varied compared to what you’ll see on your computer screen. Avoid making brightness a key component of your design since printers won’t be able to reproduce vivid colors precisely.

Although we accept files in different color spaces, our system only works in RGB (red, green, and blue). Please note that we will convert any CMYK (cyan, magenta, yellow, and black) files you upload to RGB.

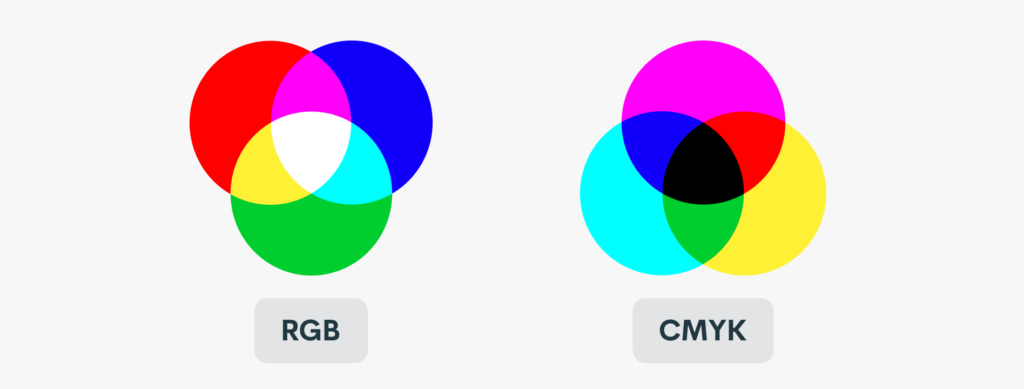

RGB vs. CMYK

People, computers, and printers view colors differently. The human eye is capable of seeing so called ‘visible light’ – the range of the electromagnetic spectrum between infrared and ultraviolet, that is basically equivalent to the colors of the rainbow.

Computers, on the other hand, are programmed to distinguish different tints and colors of specific red, green, and blue compositions.

And, last but not least, printers operate in yet another coding scheme: cyan, magenta, yellow, and black (CMYK).

If these three perspectives don’t line up correctly, an end product’s print colors will look different from that same item on a computer screen. Learn how to get the best print color to match your vision with the final product as much as possible.

RGB to CMYK

When someone makes or uploads a design with different print colors, the image is saved in computer software as RGB. However, before the design is printed, that RGB format must be converted into CMYK.

This is because, instead of a screen projecting various print colors, the tints we perceive on a garment are only the reflected wavelengths of visible light.

Print Colors and What Affects Them

Our print providers convert the design files to the appropriate color space and profile, depending on their process. Please be aware that physical printing limitations cannot produce the full range of RGB spectrum.

Each printing company uses different software for converting files. Not only that, but their printers, color profiles, settings, and processes also differ. Color inconsistencies are sometimes a problem, especially for DTG printing. So your prints can vary depending on many different factors.

- Printer errors

- Print provider’s workflow

- Garment color and material

- Your monitor settings, and more.

Note

To achieve brighter print colors for your products, consult our guide on RGB vs CMYK.

Here is an example of a common issue in how a computer will display your design and how the garment will look once printed when it comes to color consistency in printing and publishing across the web.

Our Product Creator displays product previews in RGB by default. That means that regardless of the colorspace you use, your design will be converted to RGB once you upload it.

Print Providers usually print in CMYK, but you can check how the product will look after printing with the Product Creator. Preview your creation in both color profiles, check for differences, and fine-tune your designs if necessary.

That way, the final results will be much closer to the mockup without significant color shifts.

These steps are essential for those who prefer using exotic or unique print colors, as they may not perfectly match what you see on a screen.

AOP Color Limitations

The conversion is not the only aspect affecting your final print. Each print provider uses different equipment for different printing methods, resulting in slight discrepancies in the color, especially for all-over-print (AOP) products.

For example, many of the blank items used – such as tees, leggings, hoods, etc. – are white by default and are then printed on with your colors and designs. As the garment itself is white, putting a pitch-black color or design on top may sometimes translate to a gray/charcoal gray tone. Any intense and dark or bright colors might not come out as vibrant as you’d like.

Why? This is due to the bright ink being unable to fully penetrate white fabric, therefore bringing down the tone’s opaqueness. In short, the white fabric still shows through and makes for a more translucent tone.

Shades of Blue

Printing blue and purple tones can be extra tricky since the two are very close within the color spectrum. Both navy blue and dark purple colors are known to shift.

Different shades of blue that are similar to purple tones can be printed as purple shades – and vice versa, due to color conversion. If you’re worried about the final print regarding your blue shades, try adjusting the colors accordingly on your software.

You need to change the color settings to evade undesired shades of blue or purple. To avoid purple, use a small percentage of magenta and a heavy percentage of cyan (the difference should be 30-40%). To avoid blue, reduce the percentage of cyan and increase the one for magenta.

While this affects shades of blue the most, the same principle applies to yellow-orange and other close-color inconsistencies. Keep the color-mixing process in mind when designing, and remember that the physical color output might differ slightly.

Note

These are general guidelines since there are many different factors (listed above) that can affect the final print.

- Table of Contents

- RGB vs. CMYK

- Print Colors and What Affects Them