DTG Specifics

Chapter 5

DTG Specifics

Direct To Garment printing is not the old-school, iron-on transfer that fades rapidly with time.

DTG printing reminds the document printing. A high-resolution digital image is transferred directly onto a shirt.

DTG colors are comparable to those in a CMYK color range used by conventional document printers. This is an excellent method for printing in small quantities.The small elements will also be printed in a higher quality and the images will look sharper compared to the screen printing method.

Material Absorption

The color of a material plays a role in how designs appear on final products. Using the example of an identical design printed on two different products (one thin and one thick), the thinner material will absorb the ink a bit better. So, the thicker variation will have a more prominent layer of paint – this helps the design stand out.

Zero Setup

DTG printing is a quick and easy way to print products, compared to other traditional printing methods. This is particularly beneficial for small orders that can be processed and shipped quickly.

Looks Great

DTG prints look as good or even better than other printing processes, such as screen printing. This means you get high-quality products at low prices.

Detailed Images

One of the main reasons DTG has been chosen by so many designers and creatives, and has somewhat revolutionized the printing and merchandise industries, is the ability to produce very detailed graphics. Follow our guidelines on file size and colors, and create with ease.

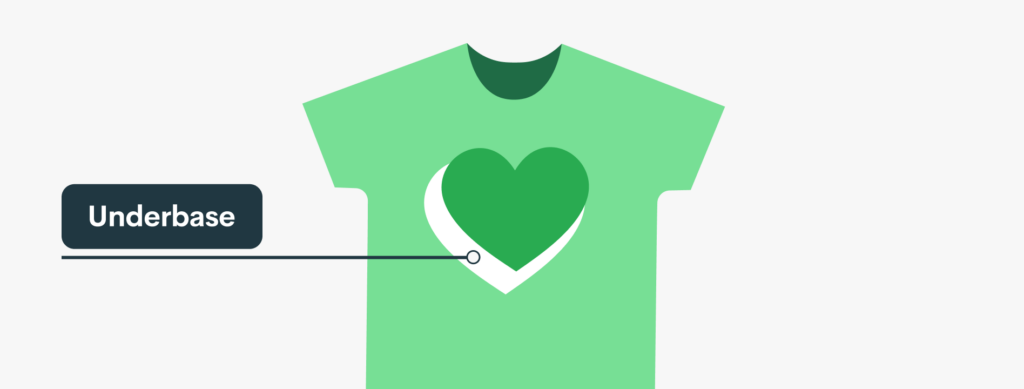

What Is Underbase

Except for white clothing, all DTG fabrics have a white underbase applied to them. Your design is printed on this underbase, making the colors vivid and detailed. At the same time, the underbase makes color gradation complex. While a gradient might look beautiful on a white garment, it won’t look great on a black one.

- Table of Contents

- Material Absorption

- Zero Setup

- Looks Great

- Detailed Images

- What Is Underbase