Choosing a T-Shirt Fit, Style, Sleeves, and More

When it comes to making corporeal decisions about shirt selection, there are a few clearly defined areas to keep in mind. Now, if there’s a direction that you absolutely must go in, best of luck to you. However, it may be best to stick to styles with a broader, more researched appeal.

With all the t-shirt variations out there, these are some good guidelines to consider. Please be aware that there may be some overlap in the explanations below, as these categories detail similar characteristics and fields.

1. Neckline: Just like the number of styles out there, this feature is central to cultivating a particular look. Even if the other facets of a particular garment are ideally situated relative to a particular body, getting a neckline wrong can be a deal-breaker.

2. Style: Instead of this meaning the shirt has a look fitted, tailored even, to a specific person’s body, it more means how the basic shaping of the garment drapes around the body. The garment shouldn’t result in impingements, discomforts, or restrictions in locations like the arms, shoulders, chest, or back. However, the fit can be highly subjective – as there are many styles that can call for a tighter or baggier placing.

3. Sleeve: The name for the cloth covering over the arms of a garment, sleeves come in all shapes and sizes. Depending on the particulars of a given person’s body (shoulder width, arm length, etc.) affect the overall look of a garment, this aspect is crucial.

4. Fit: What activities does a shirt allow the wearer to participate in? For example, depending on a shirt’s particulars, an occupant’s dress suitable for a sporting event might not feel comfortable dressed similarly during business casual work hours. The function of the shirt is key.

5. Fabric: The composition of a shirt is arguably the foremost factor in shirt selection for both print-on-demand merchants and their customers. If Something looks amazing, but is uncomfortable to wear – too tight, itchy, scratchy, nonfunctional, etc., they won’t get much traction with customers.

6. Dimensions: As different shirts are meant for different occasions, activities, seasons, etc., how heavy, thick, and weighty a particular fabric is makes a huge impact on when, where, and how it can be worn.

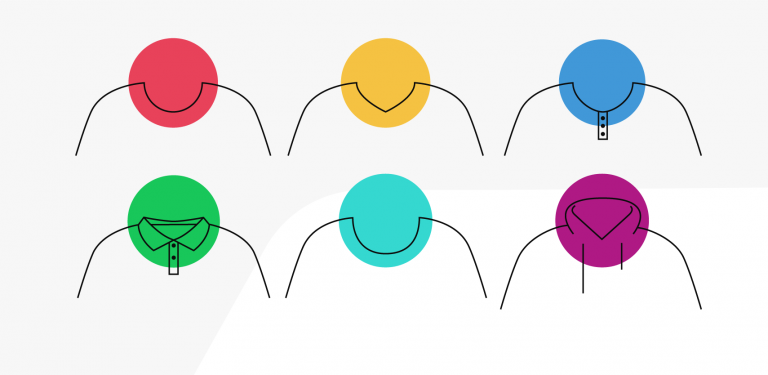

1. Neckline

Just like the other prominent aspects of the t-shirt, a fairly diverse array of necklines have emerged. These aesthetic twists can make all the difference in product selection, as they make a prominent impact as to how wearers and customers are seen.

- Crew Neckline : A universal standard, the circular opening for the neck and head of this classically inclined tee has reached a remarkably high level of prevalence. By now, all closets have at least a few.

- V Neckline : This name implies that the seam of the collar comes down into a V shape down the front. The cut is generally recommended for those with round faces and broad shoulders. The V-taper also allows a v-neck shirt to be worn as an undershirt for a buttoned shirt with a few undone.

- Y (Henley) Neckline : Somewhere between the crew neck and the V neck, the Y neck is like a crew, but with buttons going down the front a few inches.

- Polo : The idea of a t-shirt with a fold-down collar was first popularized by golfers before spreading to the population at large.

- Scoop Neckline : With a very wide, ovular window for the head, this cut allows for a fair degree of skin visible through the extra-large opening.

- Hooded : This variation builds from the traditional crew-neck cut, but extends the edges upward and together into a hood. This addition has almost become more of a style feature than for fighting the cold - hoods even appear on tank tops nowadays.

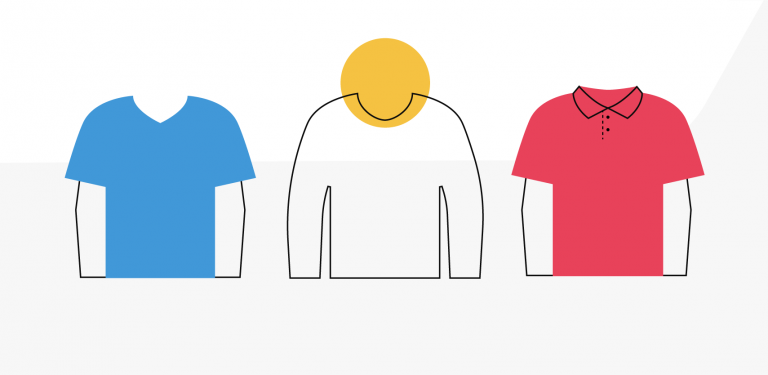

2. Style

While the position of the t-shirt is well entrenched in the conventional wardrobe, there’s still a great deal of variation within the genre. Here are just a few examples of the many t-shirt models available on the market today.

- Basic Half-Sleeve : A forerunner among the t-shirt class, this staple is original, classic, and timeless. Arguably the most popular model amongst the many here, this unisex design applies to every demographic - regardless of orientation, gender, size, age, etc. The practicality and universal appeal of this design make it a more than worthy contender for any POD merchant’s store lineup.

- Long-Sleeve Crewneck : This is a basic half-sleeve tee with the addition of longer sleeves. These make ideal layering opportunities in addition to providing a bit more warmth.

- Polo : The addition of a simple collar turns an otherwise casual garment into a slightly more formal version. As such, this inclusion can open doors, both literally and figuratively. This adaptation was widely popularized through golf before moving to its current place as a fashion staple.

- V-Neck : Sometimes called a football jersey, this tee inclusion applies a ‘v’ taper from the neck downward, rather than ovular or circular. This cutting provides a nice centering between the shoulders and chin.

- Wide-Neck (Off-Shoulder) : Predominantly preferred by women, this wide-collar shirt is designed to surround the tops of the shoulders, rather than the neck.

- Yoke-Neck tee : Sticking with the concept of a collar, these shirts often include some kind of patterned accentuation around the neck area.

- Boyfriend tee : These are looser-fit tees often marketed to women relative to the more common form-hugging models.

- Scoop-neck (douchebag) tee : This is a spin-off from a women’s wide-neck tee and adapted to a more masculine build. The extra-deep neckline displays more of the chest than a simple v - ideal for the more fashion-forward.

- Henley-collar tee : This takes the classic crew-neck tee, but takes the collar and adds a bit of a thicker neckline which leads a few inches down the front.

- Raglan-sleeve tee (¾ sleeve) : These are t-shirts with a specific sleeve type sewn directly in a line directly to the collar, covering the front of the shoulder and traps rather than functioning like the ‘normal’ sleeves attached around the shoulder. This layout results in a phenomenal range of motion. If the coloring is consistent between the two pieces of fabric, this seam can be difficult to see.

- Baseball tee : Very similar to the Raglan-sleeve tee, but with a more pronounced coloring scheme, this model was favored by baseball players taking advantage of the extra range in their sporting pursuits. The diagonal sewing pattern of the sleeves is now commonly associated with this popular design.

- Turtle-neck tee : Take a standard-issue t-shirt, then add the first few inches of a hood completed all the way around the collar. This extension can be loose or hug the neck closely. Either way, it’s an interesting choice for a base layer popular in cold or windy areas.

- Ringer tee : From the base of a crewneck tee, surround both the collar and the sleeves with a solid line. This inclusion is often a stark black (but it can be any other color) to serve as a contrast with the white base - whatever color the base happens to be.

- Cap-sleeve tee : This model has the sleeves largely removed except for a small capping over the tops of the shoulders. This puts significant emphasis on the arms - ideal for women or men wishing to draw attention to that area. Furthermore, the tight fit in the chest and stomach means these items are traditionally worn by models, gym-rats, meatheads, and barbell bunnies.

- Half tee : Sometimes referred to as a singlet by athletes - particularly runners - these loose-fitting garments are incredibly comfortable while providing excellent heat release.

- Muscle tee : Exactly what its name promises, the muscle tee is a tight-fitting, sleeveless tee designed to showcase whatever it’s worn over.

- Half-muscle tee : Take the muscle tee, and cut it in half. This model is the epitome of self-confidence - a firm display of one’s midsection under a tight, revealing shirt.

- Longline tee : This variation takes an otherwise ordinary shirt but increases the overall length past the normal hip zone. This can vary from a slight extension to hanging somewhere near the knees. Depending on who’s wearing it, this garment can contribute to an earthy, casual, or avant-garde style.

- Pocket tee : A tee with a pocket on the side just seems a bit better than a classic. It adds an uncomplicated measure of formality without staying from casual roots. Yes, the odds of actually putting anything in the pocket are low. Furthermore, the pocket can be a different color, pattern, or accent piece to add a bit of an edge.

- Babydoll tee : A throwback to the 1990s, this is a tighter fitted shirt that’s often cut shorter along the midriff or has a more dress-like lower portion. These come in both long-sleeve and short-sleeve variations.

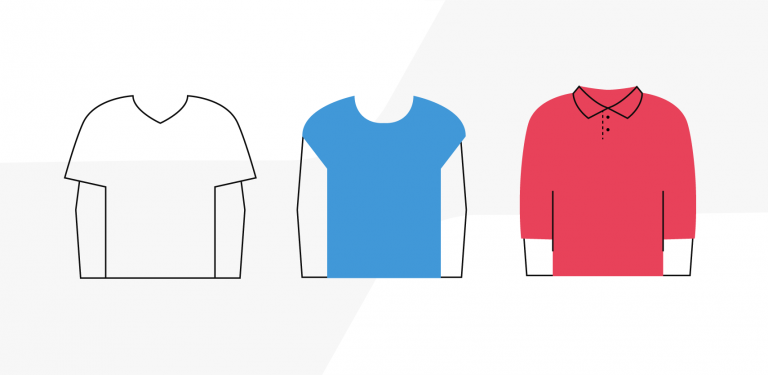

3. Sleeve

No different from any other aspect of a given t-shirt being measured for inclusion in a POD shop, a garment’s sleeves can drastically affect how a customer views a product. Everyone has a look that they gravitate to; it’s tapping into that positive inclination is the key to making sales.

- Sleeveless : Otherwise known as a tank top or cutoff, losing the sleeves entirely takes the standard-issue t-shirt and opens things up drastically. The loss of all that restrictive fabric under and around the arms allows for a supreme range of motion while allowing for unparalleled heat dispersion. Favored by athletes and gym-goers, the sleeveless t-shirt is a staple among the active population.

- Cap Sleeve : Popular amongst women and men who frequently skip leg day, this adaptation removes most of a ‘regular’ sleeve except for a small covering around the shoulders. This ‘capping’ effect brings more attention to the shoulders and upper arm.

- Regular (Half) Sleeve : The most common of all sleeve types, the regular sleeve usually falls to around halfway down the upper arm. However, this does change relative to the size and shape of the wearer. For example, an individual competing in strongman events will likely experience their shirtsleeves rising due to increased mass along the arms.

- Raglan Sleeve : Usually, but not always, having a longer sleeve than the regular sleeve, these shirts are known for the Raglan cut. This is a design whereby the shirt sleeves are connected to the shirt with a diagonal seam instead of the traditional vertical. This feature opens up the underarm of the shirt - providing an improved range of motion relative to the regular sleeve.

- Long Sleeve and ¾ Sleeve : This simply refers to the length that a sleeve runs down the arm. The long-sleeve designation indicates that the fabric around the arms proceeds to the wrist or a bit further. The ¾ sleeve usually falls to around the middle of the forearm.

4. Fit

There’s quite a disparity in the attire requirements for lounging at home against venturing out into the world. Furthermore, even beyond matters of functionality, the fitting of certain kinds of shirt fittings flatter a varying scope of body types. These differences make all the difference to customers seeking a particular product.

- Baggy : The picture that comes to mind at the word ‘baggy’ is probably an example of oversized clothing, rather than true baggy. This is a crucial difference. The baggy fit drapes over the shoulders with a larger space for the head and arms rather than a conventional fitting.

- Muscle : While this classification is a bit more prominent amongst women, a large demand for muscle shirt variations is presented by gym-bros. These shirts essentially wrap the body in a skin-suit of a different color. They’re the tightest manifestation of the tee; the ultimate expression of muscles that simply can’t be contained within the framework of a ‘conventional’ shirt.

- Regular : There’s an argument to be made that these are the best fit for a budding POD merchant. The universal appeal and practicality of these items make them fit just about any customer niche. As this is the most common, it’s worth mentioning that there are the most options (colors, sizes, models, etc.) within this genre.

- Slim : This fit wraps around the body tightly, but not as much as the muscle tee. When utilized correctly, this style is phenomenal for displaying the efforts of a disciplined workout routine. However, it’s important to consider the exact fitting, as excessive tightness or an imbalance in fabric distribution can lead to discomfort, impingement, or an uneven look.

5. Common Fabrics Used to Make T-Shirts

A shirt must feel good. If there’s a shirt (brand, style, etc.) that makes someone feel comfortable, then there’s a big pull to wear it. There’s simply no substitute for something that a customer actually wants to come into contact with. As such, the constitution of your t-shirts warrants some attention.

The composition of a garment also plays a huge role in determining just how long a shirt will last. Here are a few quality fabrics that can make sure that a particular shirt type is comfortable, durable, and acts as a good printing surface.

Natural vs. Synthetic

As a simple explanation, natural fabrics are derived from naturally occurring substances, whereas synthetics are man-made and require chemical assistance.

From there, it’s up to the merchant to decide on what characteristics are necessary for their products. Depending on what demographics are targeted, the demand will vary. If your customer base is a largely eco-friendly crowd, then a synthetic lineup probably wouldn’t go as far as a more organically manifested approach.

On the other hand, synthetics are largely built for performance. So, if the function is the pressing concern, then petroleum and blends are the way to go. Afterall, synthetics are designed to surpass their natural counterparts; they’re strong, comfortable, elastic, and retain shape well.

Cotton

This is one of the most common fabrics utilized around the world for t-shirt printing. The use of cotton is so prevalent due to the material’s widespread availability, comfort, breathability, and softness. Regarding absorbency, cotton can hold roughly 25% of its weight in water.

In the print-on-demand world, cotton is also a big deal due to how well ink sets into the fibers. In other words, cotton makes for a great printing surface.

Shrinkage : Most cotton products are preshrunk. This means that a machine has compressed the spaces between the fibers of the garment together. However, this doesn’t mean that a shirt won’t experience any shrinkage over time. It’s perfectly normal for a cotton garment to experience an often unnoticed 3-7% shrinkage in overall size throughout the life of a given shirt.

Combed Cotton

This is high-quality, super soft stuff. When ordinary cotton fiber is made, the cotton is gathered, cleaned of debris (like dirt, seeds, other plant matter, etc.), then carded. The carding process takes the random growth of the cotton and lines up the fibers so they can be spun into thread or wool.

From there, the combing process uses a series of special brushes to further refine a given batch of cotton. This combing takes out roughly 15% of a given bach’s volume – removing impurities like dirt, seeds, and fibers that are weak, short, or don’t line up with the rest of the threading. Those shorter threads are the ones that tend to poke out of shirts, causing prickling, itching, or a less than comfortable feel.

With all contaminations and substandard materials removed, combed cotton is a premier material to work with. It’s stronger, feels better, and is less likely to unravel or fray than carded open-end cotton. However, it does tend to be more expensive.

Organic Cotton

While most people are familiar with the concept of organic food, other versions of organic products still confuse many. After all, no one eats cotton. However, there are multiple, real-world reasons to utilize organic cotton relative to cheaper counterparts.

The unregulated cotton industry is one of the most chemical-intensive in the world. First, any prospective ground is cleared using fungicides, pesticides, and other predatory practices. Then synthetic fertilizers, pesticides, toxic wastes, chemicals, heavy metals, and sequences of other hazardous materials are all pumped in to boost yields, refine, whiten, finish, dye, and print. Worse still, these practices poison field workers, damage the environment as a whole, and are arguable sources of child/forced labor. All these things are direct violations of fair trade regulations.

So, while organic cotton may run a bit more than the generic option, this act is a statement in favor of both the environment and human rights. While underground production is a problem, the choice to support sustainable, eco-friendly practices is one that many customer bases identify with. In fact, many people are more than willing to pay more for items they know didn’t result in human or environmental crimes.

An easy way to sum it up is that organic cotton is grown in a way that doesn’t negatively impact the earth.

Pima/Egyptian Cotton

This is the highest grade cotton available today. What we all know of as cotton is actually a spread of three different species. By far the most common of the three is Upland cotton, composing near 90% of all production around the world. From there, it’s a split between Pima and Egyptian.

The two less frequent are simply better than the Upland variety. They naturally grow in longer, silkier fibers (also called staples). When used as the raw material for cotton production, the result is a final product far superior to Upland cotton. The use of Pima (or Egyptian) makes an amazingly soft fabric that is also strong – no fading, wrinkling, pilling, fraying, or tearing. As such, they have been officially classified as being “extra-long-staple cotton”

Ironically, Pima and Egyptian cotton come from the genus Gossypium and the family Barbadense relative to Gossypium Malvaceae for Upland Cotton. So, the only real difference lies in the geographic location. Designation Pima flourishes in the United States and Peru while Egyptian cotton grows in, you guessed it, the heat of northeastern Africa combined with the Nile River Delta. It’s also taken root big time throughout India and China.

Supima Cotton : This is basically a certification, rather than a new kind of cotton. Right now, Egyptian and Pima cotton are worth far more than Upland cotton. So, what many distributors do is cut their product with inferior materials while still charging premium prices. Unfortunately, this means that many products with a 100% Egyptian (or Pima) cotton label aren’t 100% at all. Supima solves this mess because the fabric has been authenticated by a third party dedicated to maintaining certain standards.

Slub Cotton

This designation describes a type of fabric made with small knots and knobbles – easily viewable imperfections in the surface area of a garment. But, these small raised areas of threading have actually become a desirable feature – particularly among the avant-garde fashion scene.

The elevated areas of the shirt’s surface are made during the process of weaving the cotton into thread. As the threads of cotton are twisted into yarn, small lumps form due to irregularities in the twisting. Because the surface is not meant to fall flat when worn, slub garments never need to be ironed – bonus.

Slub was universal back in the days of handspun cotton or linen garments. But now, with the use of machines, these raised bits are able to be straightened out, or included, depending on a manufacturer’s wishes.

Linen

Created from the fibers of the flax plant (Linum Linaceae), linen is prevalent in textile manufacture throughout the world. Flax is difficult to weave in its natural state, so the fibers are extracted from the plant and held in storage – letting them gradually soften over long periods of time. Currently, the term “linens” and “linen closet” are used fairly often to refer to fabrics – even if the items being referred to aren’t made from linen.

Linen is renowned for its durability, strength, and longevity. This is primarily due to the fact that the cellulose fibers are longer and tighter than those of cotton yarn. When it comes to softness, linen often needs a few washes to get rid of a router feel. However, once this process is complete, the fabric becomes very soft and lightweight.

The rougher, textured patterning of linen makes for great breathability. Linen can also hold up to 20% of its weight in water. The water-wicking ability of linen is legendary, as the fabric is able to draw moisture (or sweat) away from the skin for evaporation. This effect also makes it a good choice for hotter months, as linen fibers have gaps that allow heat to dissipate.

It’s also known for its hypoallergenic properties. The lower thread count combined with a slightly looser weave traps less dust, dirt, and other particles.

Polyester

Polyester is a blanket term for any fabric derived from petroleum. First synthesized by the English as Terylene in 1926, Americans mass-produced this durable synthetic fabric for war needs throughout WWII. After the fighting ended, companies needed to keep the machines running to turn a profit, enter polyester clothing.

Now, it’s one of the world’s most popular fabrics – utilized throughout thousands of industries and applications. China, Taiwan, Japan, Indonesia, India, and Korea are all major producers – with smaller manufacturing occurring in the United States.

This prevalence is largely due to how cheap the material is to make relative to an impressive amount of durability, ability to hold printed designs well, and quick-dry capabilities. While some garments go 100% polyester, it’s also very common for other fabrics to be blended in.

There are three types of polyester: Ethylene Polyester, Plant-Based Polyester, and PCDT Polyester.

- Ethylene Polyester : More commonly known as PET, this is easily the most popular form of Polyester. When people talk about polyester, they’re usually referring to PET.

- Plant-Based Polyester : This is a biodegradable alternate option to the cheaper, more conventional Ethylene Polyester. While having clear environmental benefits, this derivative is less durable and costs significantly more to create than PET or PCDT.

- PCDT Polyester : This fabric is far more elastic than regular Ethylene Polyester. This makes it a perfect fit for certain situations. As the durability is also increased dramatically, this fabric is preferred for situations requiring thicker, stronger fabrics - like drapes, curtains, or upholstery.

Consequences : Unfortunately for shirts composed of or including polyester, virtually every stage of the polyester lifecycles has a negative, lasting impact. Fossil fuels serve as raw material, itself an issue compounded by the inefficient, wasteful methods used to extract it. Then, oil refineries break down that complex, dense matter into its respective components. These are reconfigured into whatever the engineers, scientists, or politicians want. These refinement and processing stages each produce dangerous synthetic byproducts – similar to many of the other large-scale industries modern civilization depends on.

Poly-Cotton

A split between cotton and polyester is a pretty common sight these days. The most popular ratio for casual wear is 50/50 while athletics and athleisure gravitate toward a weighted 65/35. As cotton is a more spacious fabric (space between the fibers), the polyester can be interwoven cleanly. It makes sense, as this combines the best aspects of both the natural and synthetic worlds into a superior hybrid.

Cotton isn’t the most durable fabric. While it is breathable, the material wears out and rips much more easily than when bolstered with polyester. For this reason, 100% cotton garments need a bit more care over their lifetimes than a blend. A good example of this is ironing – polyester keeps things wrinkle-free. As such, these combinations can handle more washes without fading or losing their feel.

On its own, polyester isn’t a very breathable fabric. Things can get sweaty and material has a habit of sticking to the skin. Furthermore, a pure polyester garment is very prone to generating static electricity. While not directly harmful, this can be annoying when it makes hair misbehave or zaps people.

These (and other) reasons have made the poly-cotton pretty popular outside of ultra high-fashion environments. The polyester provides strength and wrinkle resistance relative to cotton’s lightness, hypoallergenic qualities, and moisture absorption.

Chief-Value Cotton (CVC) : This label is seen for blends that have more cotton than another fabric – usually, but not always, polyester.

Rayon

The actual properties of the fabric are as strange as its designation as a ‘semi-synthetic’ material. Rayon has the ability to take on the properties of many other textiles, including cotton, wool, silk, etc. This universality has made it a prime candidate for inclusion with just about any other fabric – which is fairly common.

Rayon is a blanket term for any synthetic or semi-synthetic fiber made from cellulose. Anyway, it was invented to replace silk, and as a result, it’s sometimes called artificial silk. It’s currently the most popular fabric for women’s clothing, largely responsible for clothing that has a flowy vibe to it. Imagine a flag. That wafting of the fabric through the air is the idea – but for clothing.

Rayon is made from the mechanical pulping of cellulose from wood pulp or cotton. Then, the mash is treated and liquified using chemical solutions. That soup is then extruded (forced through) the very small holes of a metal device called a spinneret. This produces fine threading that is washed in a chemical bath. Strengthened by this dip, the fibers proceed to a finishing process that spins them into yarn. Ultimately, production is a chemistry-rich process that starts with natural components – explains the semi-synthetic classification.

Tri-Blend

This concept is most often a combination of cotton, polyester, and rayon. However, other combinations of three or more are out there. Essentially, these are the result of a deeper examination of the pros and cons of each fabric type. By including the best aspects of each contributor, the result is a final product far beyond the limitations of other fabrics. Odds are, these are the most expensive. But, premium items go for premium prices, so it’s really all up to merchants to weigh the merit for themselves.

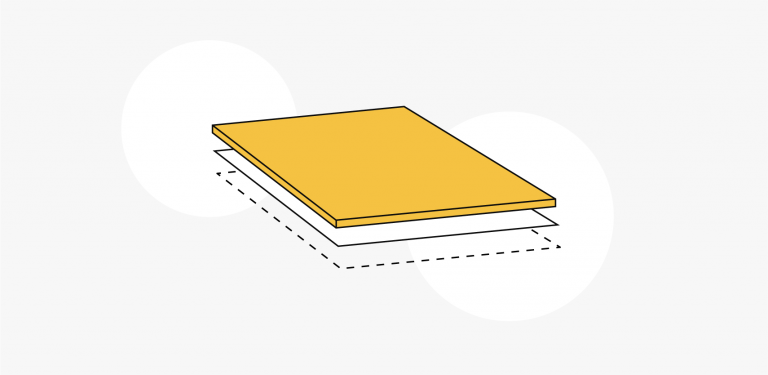

6. Dimensions

It’s no fun to wear a super-thick t-shirt during a summer heatwave or a light covering during an event with some wind chill. Odds are, we’ve all experienced a bit of a wardrobe malfunction at some point that could’ve been eased by stripping down or jacketing up. For these (and other) reasons, the geographic location is a critical factor in determining whether a particular t-shirt sells. Weight also plays a role in wrinkling and if a shirt appears sheer or opaque.

Metrics: Inches (“), ounces (oz), and grams per square meter (gsm) are used for measuring respective dimensions.

Fabric Thickness

In addition to the composition of the fabric making a significant difference when it comes to how a shirt performs, it’s also a critical factor to how much fabric is involved in the construction of a shirt. Here are a few of the more common fabric thicknesses.

Not all shirts may perfectly conform to the examples included herein.

- Super Light : The lightest and most breathable option on the market, superlight t-shirts usually fall between 0.006” - 0.007” in thickness. This incredibly narrow barrier means that many of these garments are partially see-through. However, this transparency effect diminishes somewhat with darker colors. Due to the thinness of the fabric, they do tend to wrinkle more. However, that slender threshold makes for incredible breathability during hotter weather. The silky feel to a super light is a pleasure to encounter, but a vulnerability to tearing comes with that richness.

- Light : With a bit more heft than the super lightweight variation, the light version is more of an all-year-’round piece. It can serve as an undershirt to protect outerwear while not resulting in the rapid overheating that thicker shirts can contribute to. As they are still relatively thin, wrinkling can occur. However, there are wrinkle-free and iron-free manifestations widely available. These are prevalent throughout relaxed-business to casual wear due to how they drape over the body. However, this tightness can be uncomfortable for customers wishing to hide unwanted curvature. This category traditionally stretches to 0.008” in fabric width. The weight here produces a soft, buttery feeling to the fabric - a significant reason why they’re purchased in stores. If someone likes the feel in their hands, the logical conclusion is it would feel even better against the body.

- Medium : This is a popular go-to for many t-shirt sellers. There’s no opacity except for a bit of show-through with whiter tees. The sturdier build of these fabrics means they’re fairly resistant to wrinkling. However, many non-iron options exist. While this category leans toward the more casual side, there are exceptions. Mediums often fall around 0.009”.

- Medium Heavy : Gravitating more toward simple outerwear proposed for a cool-to-windy day, the medium-heavy t-shirt is fairly warm due to their significantly higher thickness (0.010’ - 0.011”), relative to other styles. This version also moves up the ladder of wrinkle resistance from lighter fabrics. As a great many t-shirts are produced in this genre, it’s likely a few are still lingering in your closet. Their build makes them extremely durable. That longevity is a double-edged sword. If you like it, it’ll be there forever… But if you don’t, it’ll be a waste of closet space for the same time period.

- Heavy : Some of the thickest (0.012” - 0.014”) and heaviest shirts available, these garments are purposed for heavy weather and winter climates. They retain heat significantly better than their thinner counterparts. Flannels are often made from this type of material due to its durability, warmth, and styling.

- Super-Heavy : The weightiest of the bunch, the super-heavy (0.015”) is often seen as denim. Therefore, this material is very rare for a t-shirt. However, as all things are possible these days, maybe a denim t-shirt could become the next high-fashion standard.

Shirt Weight

This is another critical metric for measuring the composition of a shirt. T-shirts are traditionally measured in ounces (oz). Now, using the example of a shirt measured at 5 oz, the shirt will actually weigh more than 5 oz when placed on a scale. This is because different shirts can have different weights. Therefore, it’s more accurate to measure the shirt’s fabric weight, rather than the finished product. So, for that same five-ounce shirt, the real measurement is five ounces per square yard. This practice makes scaling much easier, as the raw material can be used, rather than weighing each shirt for an average there.

- Light-Weight Shirts : These are all less than 5 ounces per square yard. Or in the metric system, below 170 grams per square meter.

- Medium-Weight Shirts : These are often somewhere around 5 ounces per square yard. Or in the metric system, about 170 grams per square meter.

- Heavyweight shirts : These are all 6 ounces per square yard or above. Or in the metric system, roughly 200 grams per square meter or more.

7. How to Choose a T-Shirt Style

As ours is the age of athleisure, the t-shirt is a garment many people will live in. As they’re so prevalent, this means that finding that fitting is a big selling point for any POD merchants.

As we’re all experts in the court of our internal opinion, one of the best ways to discern the needs of customers is to analyze your own preferences. There’s probably at least a few favorite shirts in your wardrobe. Consider what makes them so valuable. The reasons are probably somewhere along fit, feel, design, fond memories, etc.

Tapping into a demographic’s needs, vibe, and energy is what makes t-shirts sell. It’s all about whatever the targets of a given product line resonate with. If you’re having some trouble thinking up how this could work, here are a few mellow examples of store angles to help get the creative juices flowing:

- Old-School Beach Vibe : First, slap some palm trees above gentle lapping waves with a drizzle of psychedelic coloring for your design. The beach crowd is usually pretty crunchy, so consider the eco-implications of the blank’s shirt’s sourcing, labor, etc. Lastly, wrap everything up with a model that’s light and breezy. Now, that’s a shirt that could appear above some board shorts or bikini bottoms.

- Sports Events : Design here may be a little trickier. Most sports teams, mascots, etc., and other notable figures are considered intellectual property. So, this means you can’t make money from copying someone else’s stuff. Instead, focus on aspects of the game, messages, and color schemes that your audience can connect with. Then distribution and trending factors are key. If a team is hot, and you can score a few sales by slipping under the pricing radar, maybe a cheaper build is best. However, people are more likely to wear a garment more often if it is of higher quality.

- Social Justice : What do you stand for? The beauty of this ultra-accessible medium is it gives anyone with an opinion a platform to showcase it. If a shirt is destined for the crucible of front-line demonstration, a cheaper, more replaceable base may be preferred. However, in staying aligned with the roots of the movement, the sustainability and human cost of garments should be factored in. Whether you’re speaking truth to power or pushing awareness of a particular subject, the social justice tee is on the rise.

- Everyday Ordinary : For those occupying the middle ground of the human bell curve, there’s a significant need. After all, the majority of the population (and therefore the entire market) falls here. These individuals gravitate toward models that incorporate a predominantly comfortable application. Make this niche happy by not pushing too hard in any given direction save casual. Use softer, medium-fit tees in more generalized colors that allow the individual to express a less extravagant attitude.

- Peacock : We’ve all seen them. After all, how could you not? This niche desires the exact opposite of the pigeons around them - they want to shine. Only the highest of quality fabrics coupled with bright, extravagant designs, and hard-hitting colors will do. Hit these high-rollers with a few products that quite literally cannot be missed and draw in a few whales.